XLY-250 Liquid Filling Machine

Feature

1. Easy to operate and maintain.

2. The equipment is composed of branded electrical components and runs stably.

3. Stainless steel body, strong and beautiful.

4. It has a wide range of applications and can be customized according to customer needs.

5. It can meet international standards and is harmless to humans or the environment.

6. Automate production, reduce labor and increase output.

7. Intelligent adjustment, simple operation, induction filling, precise measurement.

8. Cylinder positioning, automatic bottle feeding, no filling without bottle, automatic stop and start.

9. Microcomputer control, more stable filling, higher precision, small repeat error.

10.All stainless steel body, laser cutting, smooth surface without hurting hands.

11.Independent motor control for each head, digital display speed regulation, adjustable flow rate.

Machine parameters

| Type | XLY-250 |

| Voltage | AC 220V/50-60HZ |

| Motor Power | 1000W |

| Filling Speed | 16-24 B/Min |

| Filling Volume | 20- 100, 30-300, 50-500, 100-1000, 500-2500, 1000-5000ml |

| Filling Accuracy | ±1%(Depends on actual filling material) |

| Filling Head | 4 |

| Machine Size | 2165*1210* 2010mm |

| Package Weight | 395KG |

Application

This machine is used for filling various liquid materials such as juice, liquid sauce and low viscosity oil.

It has the advantages of high precision filling machine and small size of the machine. The part in contact

with the material is made of 304 material,which can meet the requirements of food grade and is widely

used in various daily filling scenarios.

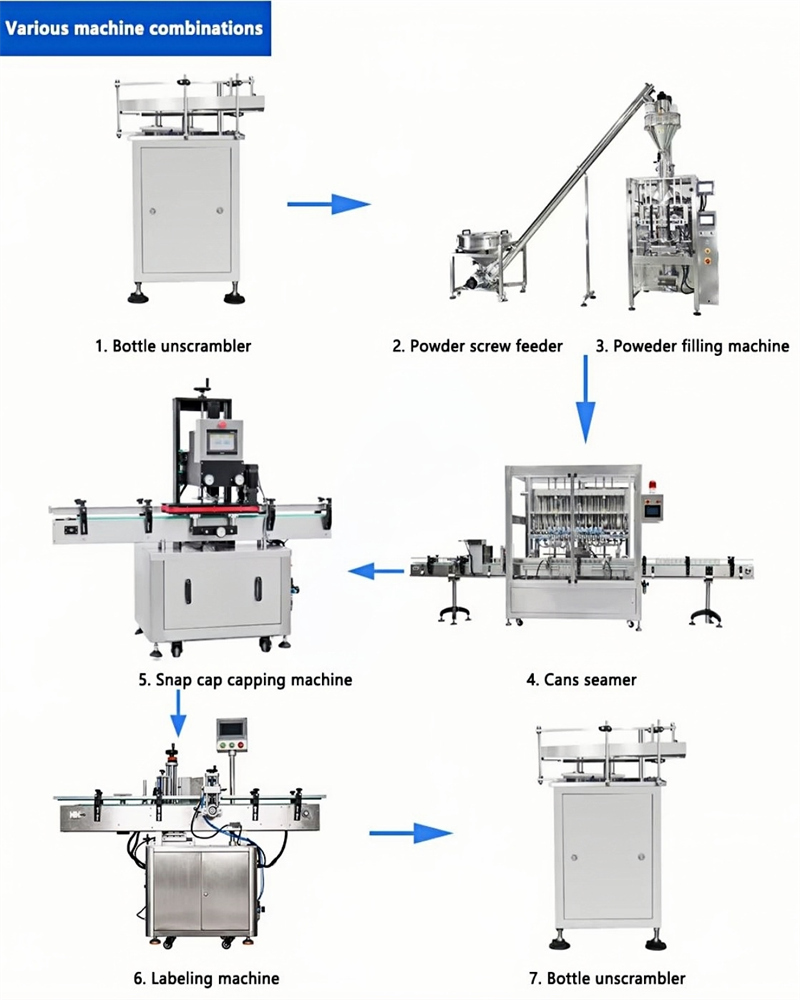

Product recommendation