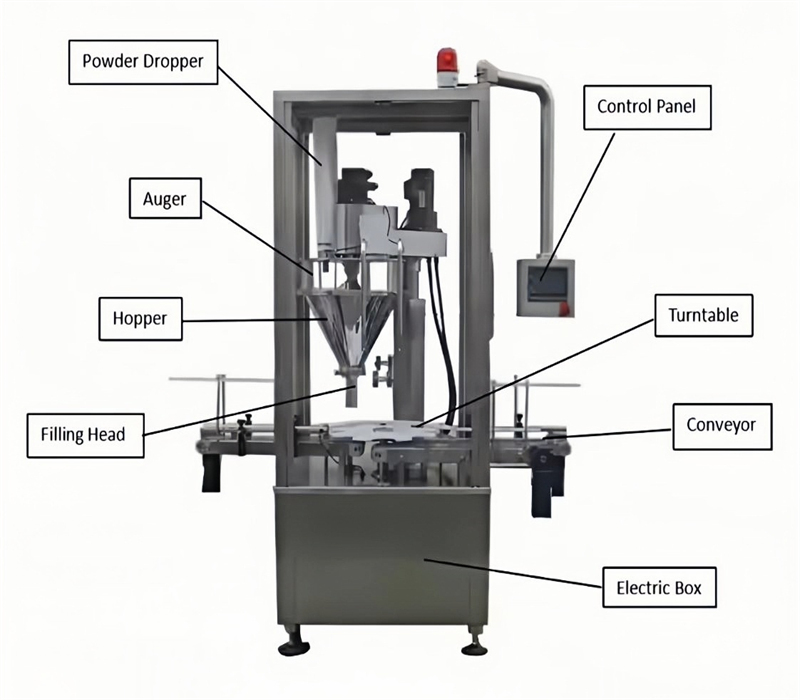

XLY-X08 Powder Filling Machine

Machine feature

1.Adopt servo system to control screw feeding, photoelectric sensor technology;

2.Transparent silo design, easy to observe the material level;

3.Stainless steel structure, stable structure, removable and easy to clean and maintain;

4.Suitable for packaging containers of bottles and cans, size and type, wide adjustable range;

5.Using world famous electronic components, reliable quality;

6.The interface can store the production parameter formula, which is convenient to use;

7.The screw can be replaced, the accuracy and efficiency can be taken into account;

8.Intelligent induction positioning and blanking without filling without tank;

9.Weighing feedback system, the error is corrected in time, and the accuracy is more stable;

10.Fault self-diagnosis alarm function, operation problems are clear;

11.All system control software can be adjusted and upgraded in future;

12.Can be used with a variety of automatic packaging equipment, convenient connection.

Machine parameters

| Type | XLY-X08 |

| Material | SUS304 |

| Production capacity | 30-60 bottles/min |

| Packing weight | 100~5000g |

| Size(L*W*H) | 3000*1200*3200mm |

| Total power | 2.3KW |

| Power supply | 380V,50-60Hz |

Application

Mainly suitable for filling and sealing of baby milk powder,protein powder, pepper powder, yam powder,

chicken powder,coffee powder and other products.