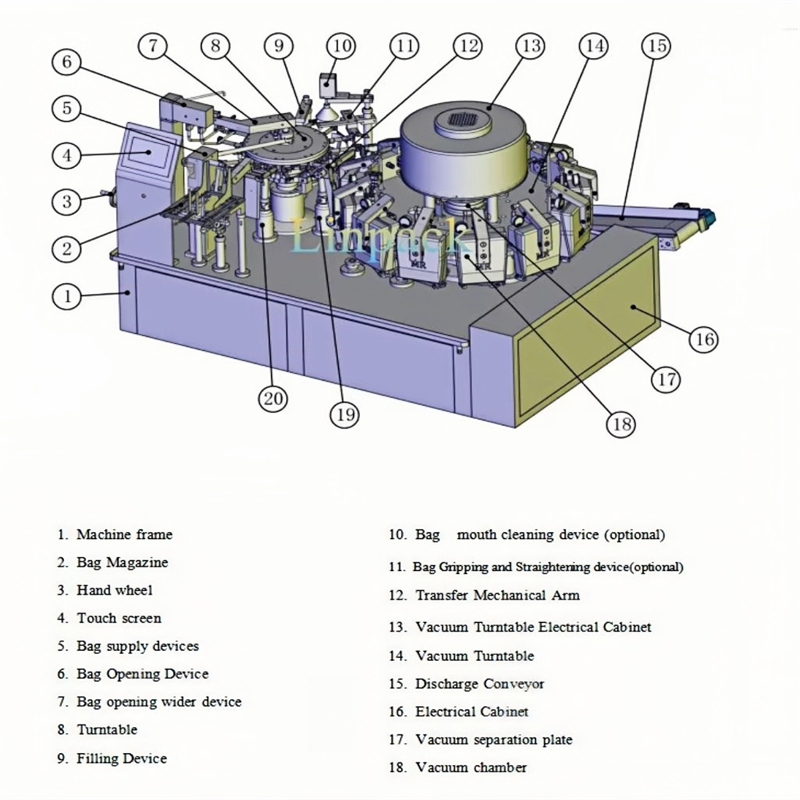

XLY8-10/160 Granule Premade Pouch Packing machine

Machine features

1. Quickly change the specifications of the packaging bag, adjust the bag width and size with a handwheel;

2. Dual axis transmission with internal cam design, fast packaging speed, more stable operation, simpler

maintenance, and reduced defect rate;

3. Modular heating, more precise temperature control, and alarm prompts for heating faults;

4. Advanced design concepts have reduced the consumption of packaging materials, ensured the stability

of equipment operation, and extended the service life of the equipment;

5. Simple and convenient operation, using advanced PLC+POD (touch screen) electrical control system

and user-friendly human-machine interface;

6. This machine uses pre made packaging bags with perfect packaging patterns and good sealing quality,

thereby improving the quality and grade of the product.

Machine parameters

Type

XLY8-10/160

Packing material

Three sided sealed bag, four sided sealed bag, independent bag, handbag, kettle bag, zipper bag, composite bag, etc

Packing bag size

W:70-160mm L:100-230mm

Filling volume

20-250g

Packing speed

30-55 bag/min (The packaging speed is determined by the product's weight)

Metering average accuracy

<±3g

Dimensions(L*W*H)

2200*1500*1900mm

Mompressed air consumption

1.0 cube/min(Compressed air is provided by the user)

Total power

380V 10kw

Application

Applied to prefabricated bag products such as agricultural products, daily necessities, food, seasonings,

hardware, electronic products, agriculture, etc.