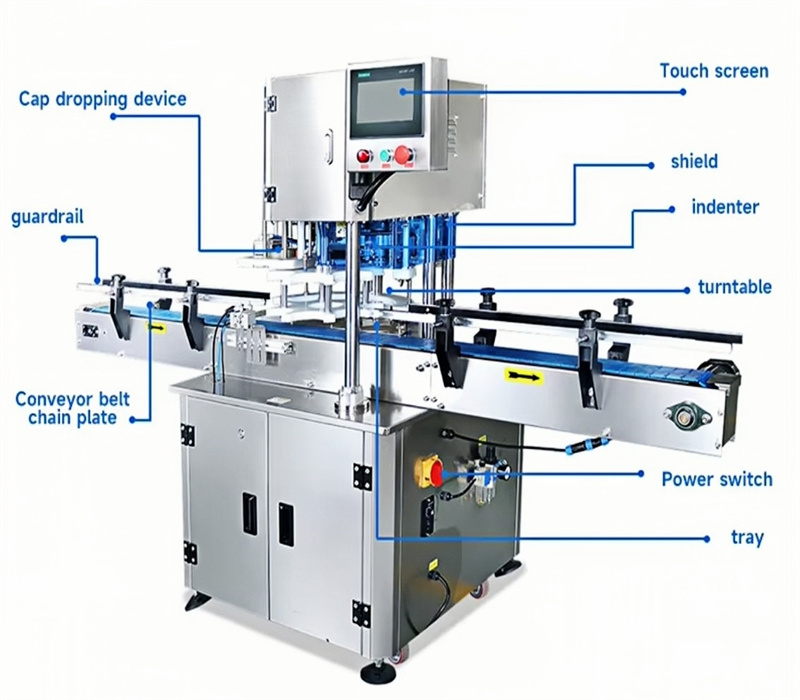

XLY-350 Powder Can Sealing Machine

Machine Features

1. Whole machine servo control makes the equipment run safer, more stable and smarter. The turntableonly runs when there is a can, speed can be adjusted separately: when there is can stuck, the turntable

will automatically stop. After one button reset, the error can be released and machine restart to run:

When there is a foreign object stuck in the turntable, it will automatically stop running to prevent artificial

Equipment damage and safety accidents caused by incorrecoperation of the equipment.

2. A total of a seaming rollers are completed at the same time to ensure high sealing performance

3. The can body does not rotate during the sealing process,which is safer and is especially,suitable for

fragile and liquid products.

4. The sealing speed is fixed at 30-50 cans per minute(adjustable), production is automated, which

improves production efficiency and saves labor costs.

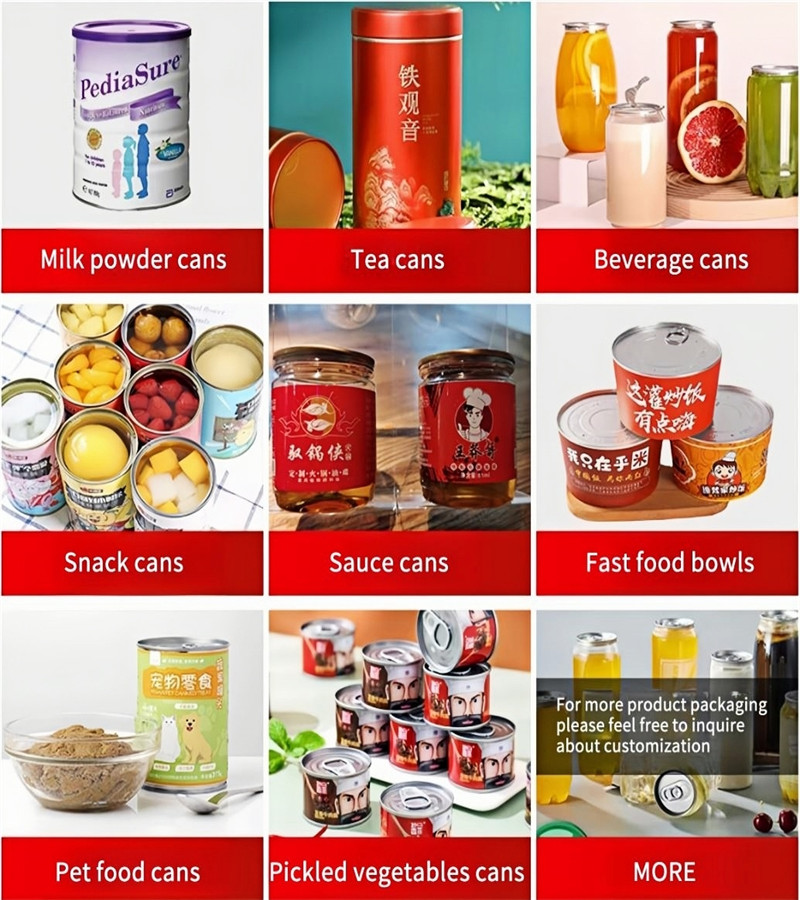

5. Applicable to tin cans, aluminum cans, plastic cans and composite paper can, it is the ideal packaging

equipment for food, beverage and other industries etc.

Machine parameters

| Model | XLY-350 |

| Number of sealing head | 1 |

| Number of seaming rollers | 4 (2 first operation, 2 second operation) |

| Sealing speed | 33 cans / min(Not adjustable) |

| Sealing height | 25-220mm, can custom |

| Sealing can diameter | 35-125mm,can custom |

| Working temperature | 0 ~ 45 ° C, working humidity: 35 ~ 85% |

| Working power supply | single-phase AC220V 50/60Hz |

| Total power | 1.7KW |

| Dimensions | L 2650* W 840* H1750mm 330kg |

Application

Widely used in food industry, chemical industry, pharmaceutical industry, suitable for particles, liquid,

powder round specifications of various tanks bodies(including plastic tubes, tinplate cans, aluminum

cans) sealed packaging.