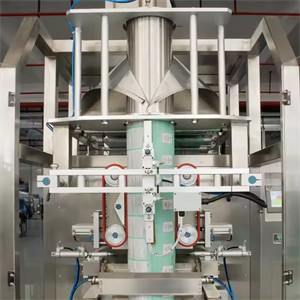

XLY-420 Liquid Vertical Form Fill Seal Machine

Machine advantage

1.Small size, low weight to be manually put into the lifter, without any space limitation;

2.Low power requirement: 220V voltage, no need dynamic electricity, and also can be customized the

power as you request;

3.operation positions, low maintenance, high steadily;

4.Fast speed, easy to be matched with other equipments, Max 55bags /min;

5.Multi-function operation, run the machine by pressing only one button, no need professional training.

Good compatibility, it can suit different types of irregular shapes of bags, easy to change the bag types

without adding extra accessories.

Machine parameters

| Model | XLY -320 | XLY-420 | XLY-520 | XLY-720 | XLY-920 | XLY-1200 |

| Film width | 120-320 mm | 420 mm | 520 mm | 720 mm | 920 mm | 1200 MM |

| Bag length | 50-200 mm | 80-300mm | 80-400mm | 80-500mm | 80-650mm | 80-750MM |

| Bag width | 50-150 mm | 50-20 mm | 70-250 mm | 60-350 mm | 200-450 mm | 200-550 MM |

| Packing grams | 50-150 ML | 50-1500ML | 50-3000ML | 50-5000ML | 100-10000ML | 100-20000ML |

| Packing speed | 35-70bpm | 35-70bpm | 35-70bpm | 35-70bpm | 35-70bpm | 35-70 bpm |

| Power | 220V/380V/50/60 HZ | |||||

| Machine dimension | 970*680*1960 mm | 1200*1500*1700 | 1500*1600*1800 | 1600*1700*1800 | 1600*1700*1800 | 1800*1700*1800 |

| Machine weight | 300 kg | 450 kg | 500kg | 600 kg | 750 kg | 1200 kg |

Application

This liquid packing machine commonly used for a variety of products, including salad dressings, jams,

sauces, and other similar food items. This type of packaging offers convenience and ease of use for

consumers. The diagonal bag packaging typically consists of a flexible plastic bag with a diagonal seal

or cut at one of the corners.

This design allows users to easily cut off the tip of the bag and squeeze or extrude the contents without

the need for additional tools or utensils. It provides a simple and mess-free way to dispense the product.