XLY-270S Powder Horizontal Packing Machine

Machine features

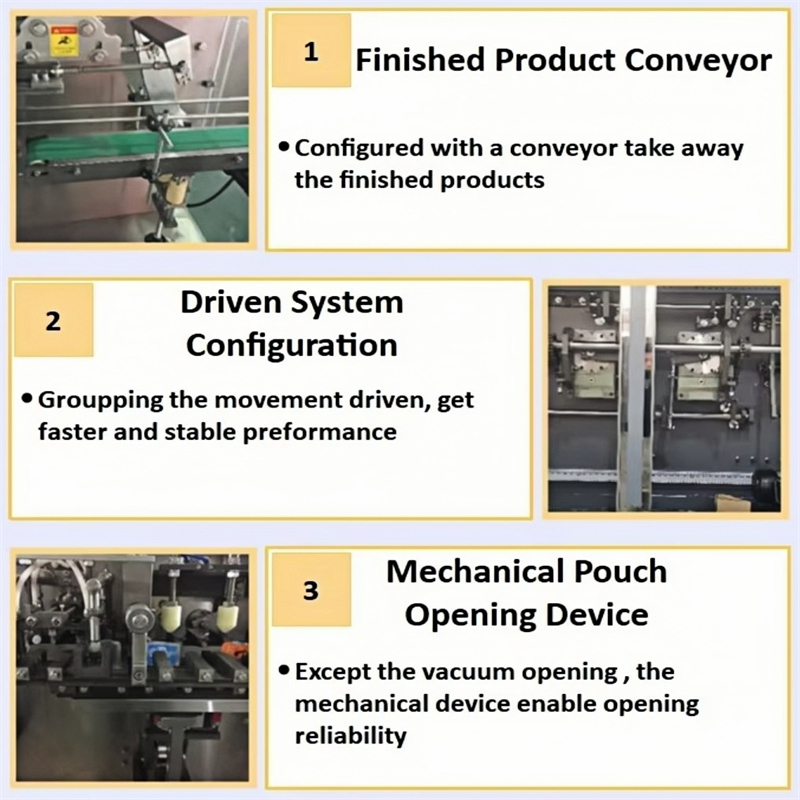

1.Automatic Stand up Pouch Doypack Filling Packing Rapid change of the specifications of the bag,

bag width can be automatically adjusted by one button;

2.Single shaft ad the CAM design, packing speed faster, more stable operation.maintenance easier

and reduce defective rate;

3. Modular heating, more accurate temperature control, heating fault can alarm;

4. Advanced design concept, reduce the loss of packaging material, ensure the stability of the operation

of equipment,prolong the operation of equipment life;

5.simple and convenient operation, using advanced PLC+POD (touch screen)electrical control system,

man-machine interface friendly;

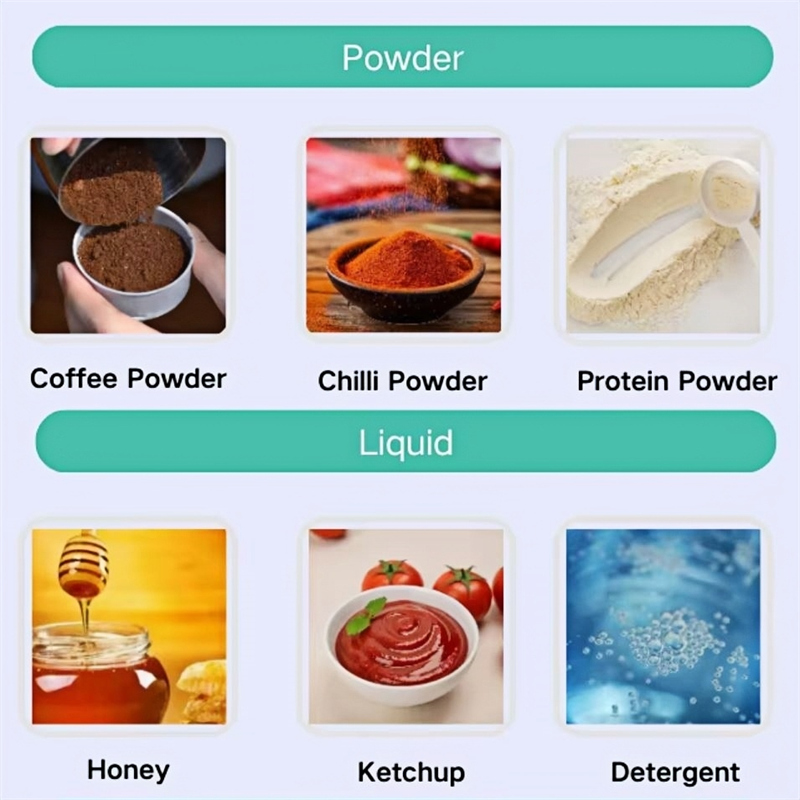

6.The machine has a wide range of packaging, packaging liquid, paste, powder particles, solid materials

just according to different materials to choose different metering device can be;

7.This machine USE s the prefabricated packing bag, the packing pattern is perfect,the sealing quality

is good, thus enhances the product quality and the class.

Machine parameters

Type

XLY-270S

packing material

Composite bags such as four sided sealed bags, aluminum foil bags, paper bags, zipper bags, self-supporting bags, M-shaped bags, etc

packing bag size

W:50-110mm H:80-160mm

packing speed

50-100 bag/min (The packaging speed is determined by the material type and filling weight)

dimensions

3100*1320*1400mm

machine weight

1800KG

Air consumption

≥0.6m³/min(Compressed air is provided by the user)

total power

5kw

Application

Type

XLY-270S

packing material

Composite bags such as four sided sealed bags, aluminum foil bags, paper bags, zipper bags, self-supporting bags, M-shaped bags, etc

packing bag size

W:50-110mm H:80-160mm

packing speed

50-100 bag/min (The packaging speed is determined by the material type and filling weight)

dimensions

3100*1320*1400mm

machine weight

1800KG

Air consumption

≥0.6m³/min(Compressed air is provided by the user)

total power

5kw

Suitable for various types of powders, such as seasonings, monosodium glutamate, milk powder,

glucose, chemical seasonings, white sugar, pesticides, fertilizers, etc.