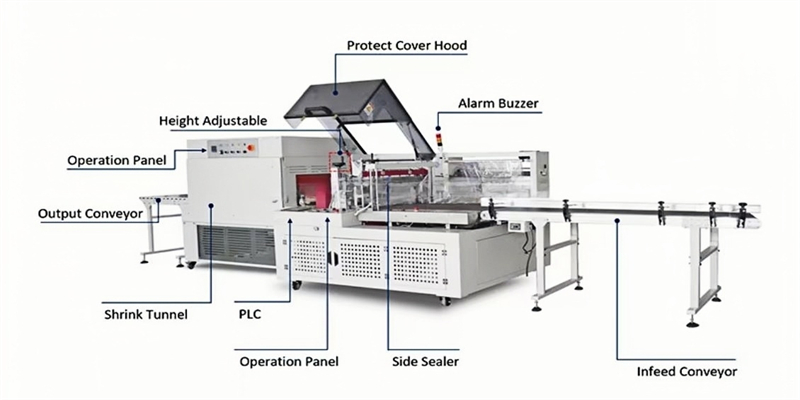

XLY-897 Automatic Shrink Wrap Machine Heat Shrink Film Machine

Machine feature

1. This machine can pack long products. there is no limit of product length because of side sealing system.

2. Special durable alloyed sealing knife with anti-stick teflon coats makes sealing strong and has better

performance of heat conduction.

3. Side sealing line can be adjusted in the center of product or other desired position.

4. Film perforating wheels can be adjusted or removed easily.

5. Only adjust packing width and height by hand wheels without changing any molds and parts when

packing size changes. packing length can be detected by the sensor automatically.

6. Operate easily and conveniently by moveable control panel.

7. Adopt siemens plc and colorful touch screen, omron temperature controller, timer, relay, switch,

and sensor.

8. A pair of photoelectric switch in vertical for thin products.

9. Optional sensor for transparent products.

Machine parameters

| Model | XLY-897 |

| Power Supply | 220V/380V; 1Phase/ 3Phase;50-60Hz |

| Maximum Sealing Height | 220mm |

| Maximum Packing Width | 600mm |

| Packing Range Limit | W + H <640mm; Length infinite |

| Packing Speed | 10-25 packs per minute (Depends on product dimensions) |

| Film Type | Center folded POF film |

| Maximum Film Roll Size | Width 730mm * Outer diameter 280mm |

| Power Consumption | 5.5kw |

| Control System | Special durable alloyed sealing knife with anti-stick Teflon coats |

| Shrink Tunnel: | |

| Power Supply | 220V/380V; 1Phase/ 3Phase; 50-60Hz |

| Tunnel Conveyor | Chains with rotating silicon coated rods/ Stainless steel net belt conveyor |

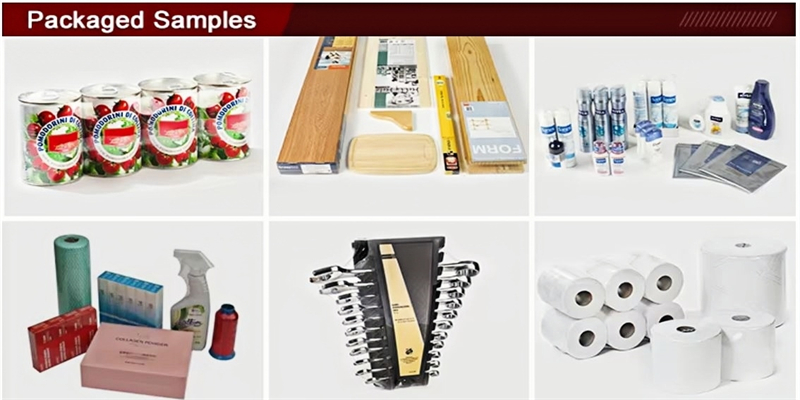

Application

Longer products such as flooring boards, paper rolls, etc.