XLY-450S Thermo shrink packaging machinery

Machine parameters

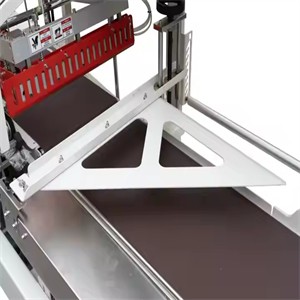

L bar sealer

Model

XLY-450S

Power supply

220V 1/3ph 50/60Hz

Power

1.8KW

Packing Size

(L+H)<550mm (W+H)<430mm (H)<130mm

Sealing Size

(L)550×(W)450mm

Table height

800mm

Packaging speed

30~50pcs/min(Determined by product size)

Driving type

Servo motor

Shrink film

POF fold film

Shrink film size

(W)≤530mm;(D)≤250mm;(weight)≤35KG

Sealing form

L type full closed

Overall dimension

(L)1800×(W)800×(H)1480mm

Package size

(L)1850×(W)900×(H)1630mm

G./N. weight

380/350KG

Heat shrink tunnel

| Model | XLY-4522N |

| Power supply | 380V 3ph 50/60 Hz |

| Power | 12KW |

| Table height | 780+50mm |

| Conveyor load | 30KG |

| Conveyor speed | 1-15m/min |

| Tunnel size(L×W×H) | 1500×450×220mm |

| Overall dimension(L×W×H) | 1910×700×1320mm |

| Package size(L×W×H) | 1960×800×1470mm |

| G./N. weight | 290/250Kg |

Feature

•The fully automatic L bar sealer which is widely used in mass production packaging line with high

efficiency.

•With movable type punching device, you can switch the punching position and control the pinholes

number.

•Using digital temperature controller which built-in PID function. Sealing blade temperature is extremely

sensitive and accurate which can be set arbitrarily.

•Adopt Panasonic PLC programmable controller and WEINVIEW 7-inch man machine interface, simple

operation.

•Equipped with automatic scrap recycling mechanism, built-in film broken alarm function.

•The sealing blade itself is also quipped with automatic protection function which effectively prevent from

accidental cutting.

•Automatic mode and manual mode can be switched at any time which convenient to replace the shrink

film.

•The entire machine realizes unmanned operation with the production line connecting.

•The shrink tunnel adopts the design of internal double recycling air fan, so that the hot air in the tunnel

is even, constant temperature.

•The machine uses stainless steel finned heating tube which has a long service life and high heating

efficiency.

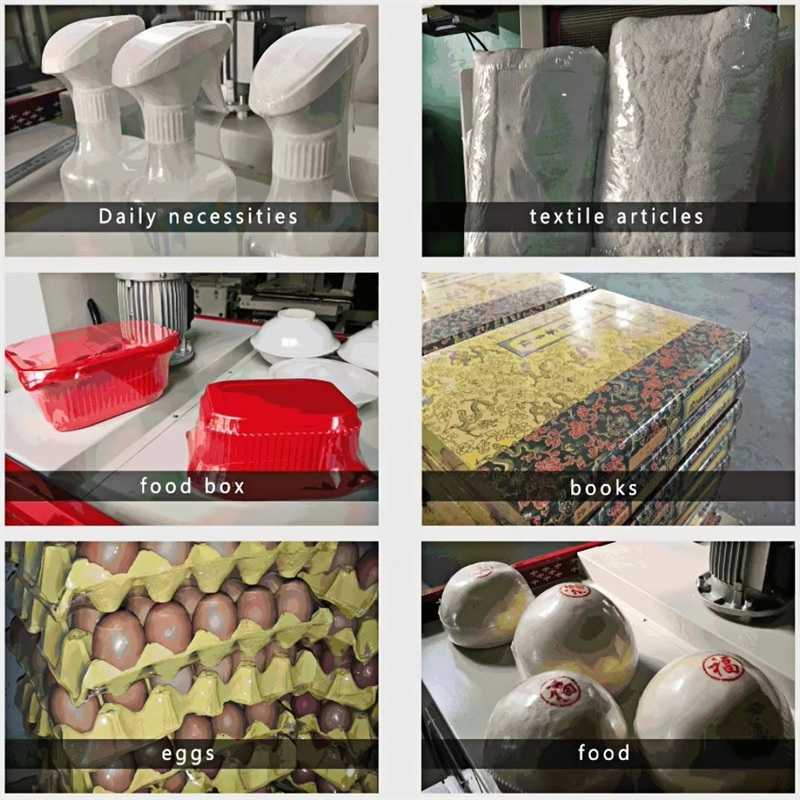

Application

Apply to daily necessities, food, cosmetics, pharmaceutical, hardware and other industries shrinking

packaging.