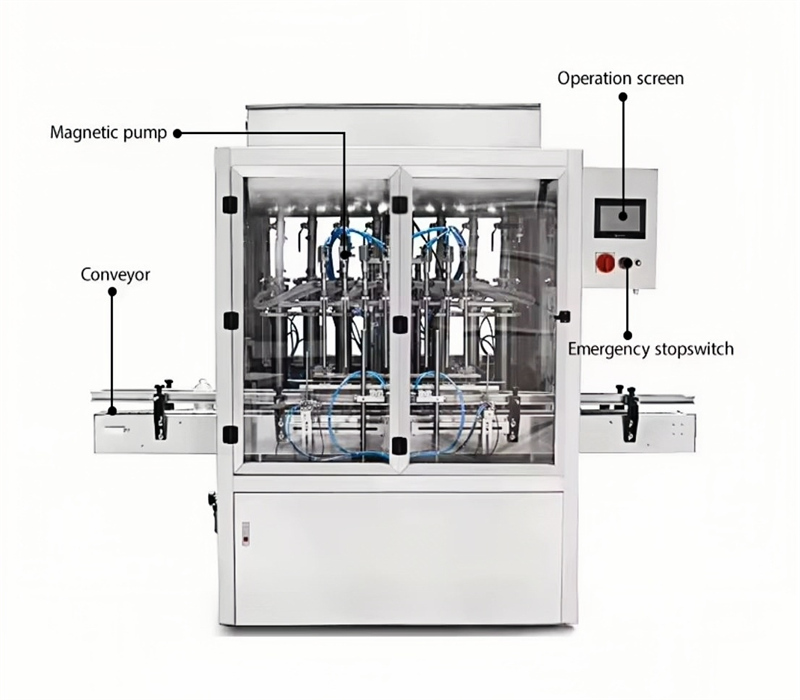

XLY-120-8 Automatic 8-head Liquid Filling Machine

Machine feature

1. Apply for filling of viscous liquid, pasty products, or sauces with soft particles.

2. Frequency converting motor driven.

3. Precision piston cylinder manufacturing technology, enable high filling accuracy and makes seal

ring more durable.

4. PLC & touch screen HMI Control.

5. Stainless steel 304 construction for main parts.

6. Stainless steel 316 construction for product touching parts.

7. Tool less for different container change over.

8. High Precision and durable piston cylinder and seal design.

9. Cleaning drain trough design, keep clean environment.

10. No container no filling interlock.

11. Quick connecting joints for pipes.

12. One key instantly set up the filling volume, no need to adjust individually.

Machine parameters

Item

XLY-120-8

XLY-500-8

XLY-1000-8

XLY-2500-8

XLY-5000-8

Filling range

(10-120)ml×8

(50-500)ml×8

(100-1000)ml×8

(250-2500)ml×8

(500-5000)ml×8

Filling speed

30-60瓶/分bottles/min

30-50瓶/分bottles/min

30-40瓶/分bottles/min

Filling precision

≦±1液体liquid ≦±2膏体liquid cream

Power

AC380V/50/60Hz 3KW

AC380V/50/60Hz 3.5KW

AC380V/50/60Hz 5KW

AC380V/50/60Hz 5.5KW

Weight

950㎏

Pressure range

0.4-0.6Mpa

Host dimension

1660×1330×2100mm

1940×1330×2100mm

2360×1450×2100mm

2800×1450×2180mm

Application

Wide filling capacity range and is suitable for many bottles/cans types.