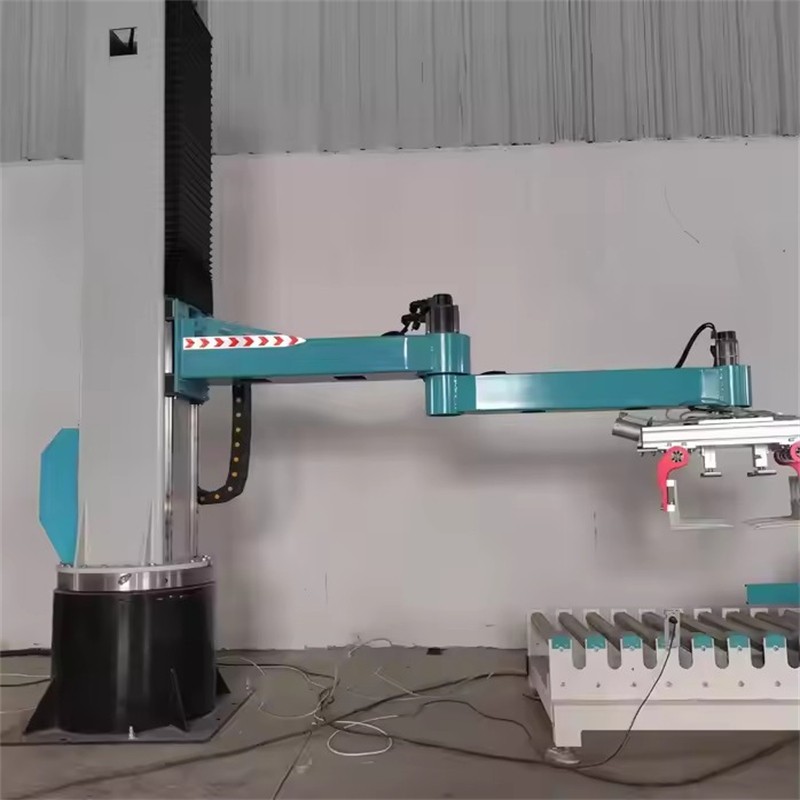

XLY-667 Palletizer Robot Stacking Bag Box Palletizer Machine

Feature

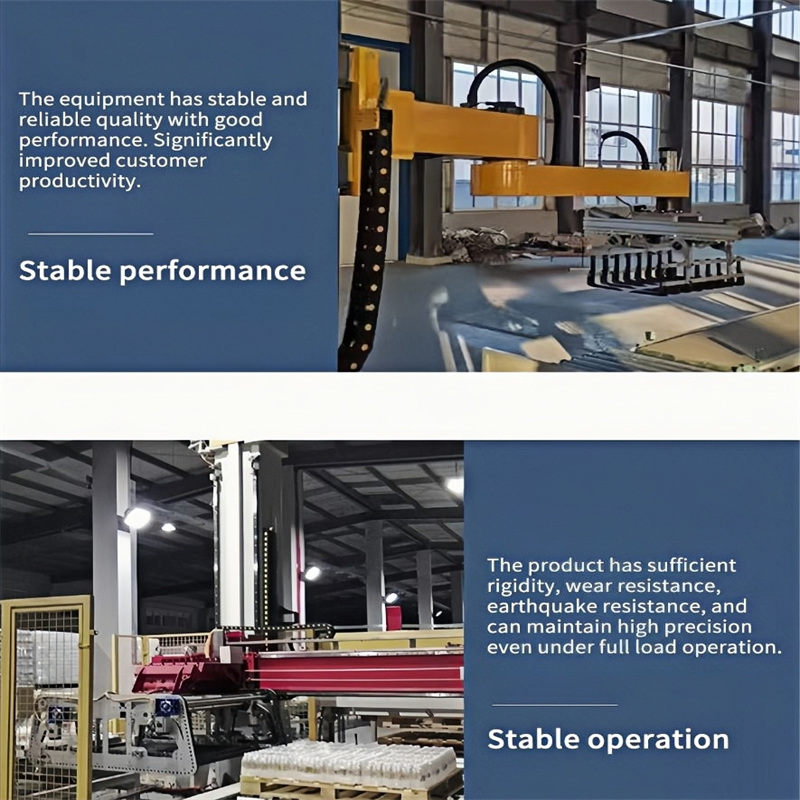

1.Reliable, long operation time.

2.Short operation cycle time.

3.High precision parts production quality is stable.

4.Strong and durable, suitable for bad production environment.

5.Good generality, flexible integration and production.

6.The ability of the robot palletizer is higher than that of mechanical palletizer and manpower.

7.Simple structure, low failure rate, easy preservation and maintenance;

8.It mainly consists of fewer parts and fewer accessories, so the maintenance costs are low;

9.Robot palletizer can be set in narrow space and can be used effectively;

10.All control can be operated on the screen of the control cabinet. The operation is very simple.

Machine parameters

| Model | XLY-667 |

| Gross Weight | 1600 kg |

| Packing capacity | 200-300 bags/h |

| Weighing Range | 20-50 Kg |

| Stacking type | 3/4/5/6/7/8/ bags per layer or customized |

| Max Stacking Height | 1800mm |

| Voltage | AC220V/AC380V/50HZ or customized needs |

| Power | 11KW |

| Air pressure | 0.6-0.8 MPa |

| Air Consumption | 1.5m³/min |

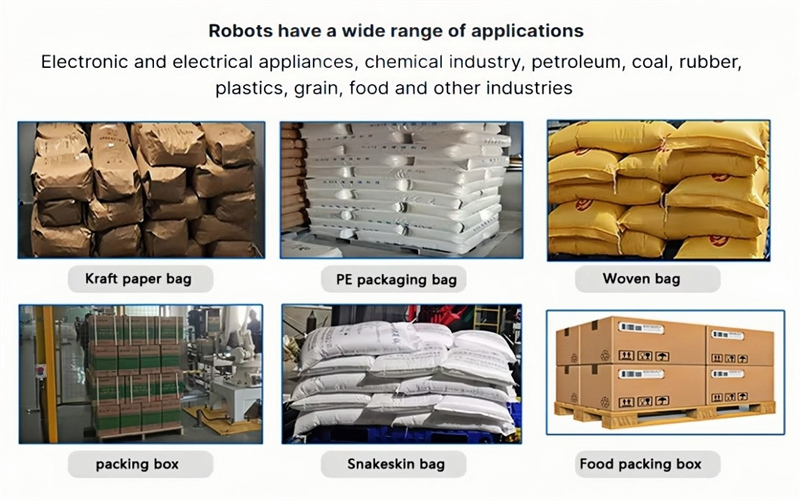

Application

Scope of application: robot palletizing machine suitable for chemical, beverage, food, beer, plastic,

air conditioning and other production enterprises for the cartons, bags, cans, boxes, bottles of finished

products of various shapes such as packing and palletizing.