XLY-T130 Automatic Bag/Box/Case Robotic Palletizer Packaging Machine

Machine description

The robot palletizer can be used at any production line, providing intelligence, robotics, and a network

for the production site. It is a palletizing logistic system that can be used in the industry of beer, beverage,

and foodstuff, etc., widely used for cartons, plastic crates, bottles, bags, barrels, shrink-wrapped products,

and cans, etc.

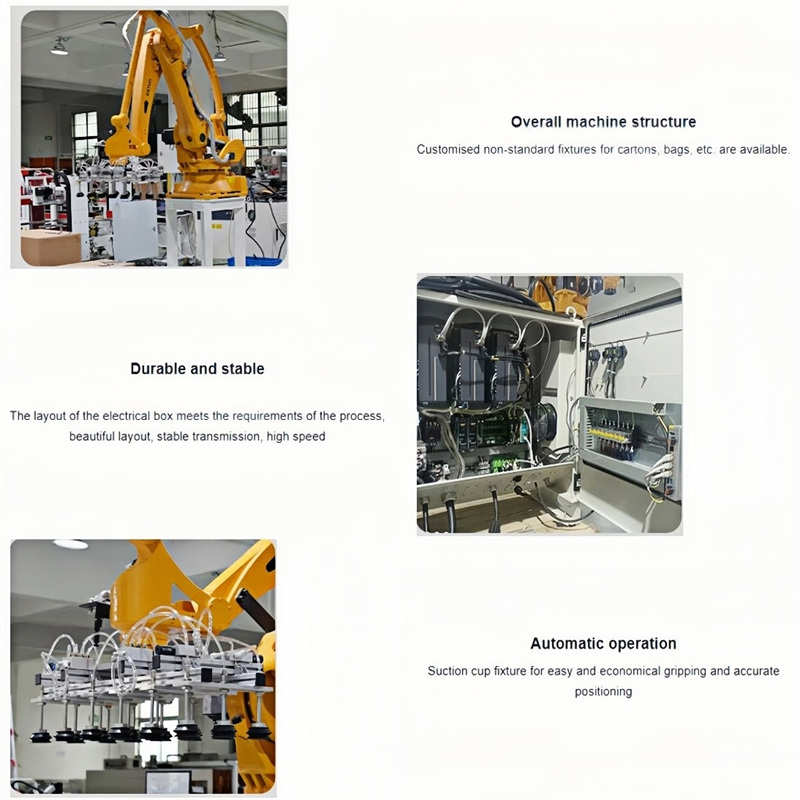

Machine Feature

1.Reliable, long operation time.

2.Short operation cycle time.

3.High precision parts production quality is stable.

4.Strong and durable, suitable for bad production environment.

5.Good generality, flexible integration and production.

6.The ability of the robot palletizer is higher than that of mechanical palletizer and manpower.

7.Simple structure, low failure rate, easy preservation and maintenance;

8.It mainly consists of fewer parts and fewer accessories, so the maintenance costs are low;

9.Robot palletizer can be set in narrow space and can be used effectively;

10.All control can be operated on the screen of the control cabinet. The operation is very simple.

Machine parameters

| Model | XLY-T130 |

| Maximum stacking height | 2500mm |

| Maximum palletizing weight | 2500kg |

| Speed | Max 800-900bags/hour |

| Power | 8KW |

| Pallet material | wood, steel, plastic or other composite materials |

| Recommended pallet size | 1400mm longx1200mm widex150~160mm high or 1200mmlongx1100mm widex150~160mm high |

Application