XLY-678 Automatic Vitamin Gummy Bottle Counting Machine

Machine description

This is an automatic gummy counter. Based on its existing technological advantages, it has the functions

of a vibration tank, pneumatic push plate, and pneumatic sleeve. The bottle and continuous feeding

mechanism have been upgraded with modular structure, and the counting photoelectric adopts one-to-one

independent control. The chewing gum counting machine has higher capsule accuracy, faster speed,

and more stable operation. The candy packaging counter can count and package solid particles such

as tablets, capsules, and pills of various specifications, with a width range of 3-40mm. It is used for

bottling, bagging, and boxing, and meets GMP requirements.

Machine parameters

| Model | XLY-678 |

| Output | Max. 55 Bottles/mins |

| Accuracy | 99.97% |

| Application | 3-40mm tablets, gummy. |

| Powder | AC380V 3P 50/60HZ(customized) |

| Size | 1100×1400×1800mm(L*W*H) |

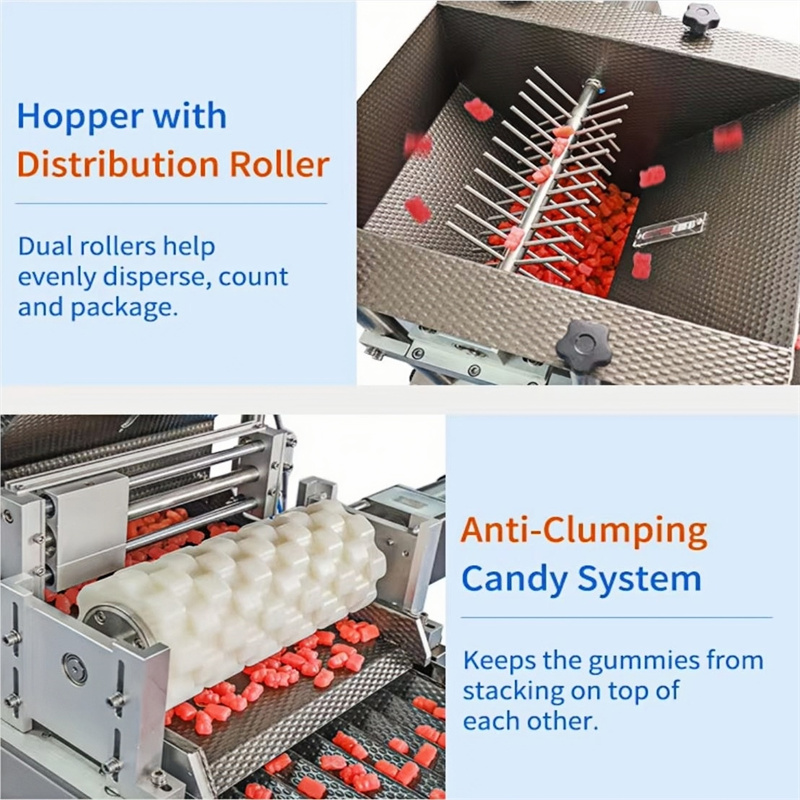

Feature

1.This series of gummy counting machine capsule adopts special electronic counting technology and

dynamic 360-degree infrared scanning throughout the entire process, detecting no dead ends and

counting pills accurately.

2.Soft candy counter has the function of automatic learning and elimination, single discovery and whole

bottle elimination.

3.This gummy vitamin bottling machine adopts a sleeve-type filling funnel. The size of the funnel is

customized according to the size of the bottle mouth to prevent materials from leaking out of the bottle

during the falling process.

4.The oscillating sliding track adopts a new stepped design and cooperates with the adjustment of the

oscillating frequency to ensure that materials are separated in an orderly manner without overlapping.

5.The PLC touch screen has a lifting adjustment function, taking into account bottles of different sizes,

making it easy to change product specifications and adjust.

6.The bottle changing uses dual cylinder positioning, and the bottle changing distance and position are

confirmed twice by the system, making the positioning accurate and reliable.

Application