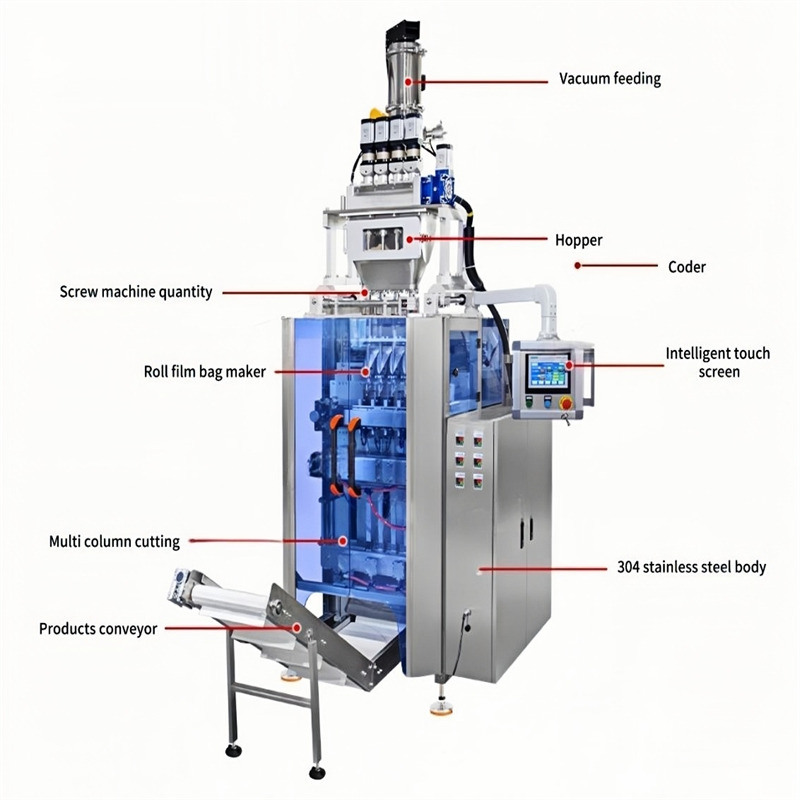

XLY-480 Powder Multi Lane Packing Machine

Machine feature

1. Servo motor to control the sachet pushing, bag forming accuracy could be assured.

2. Eye marking checking sensor to guide the forming and sealing in the correction position.

3. The machine can be equipped with supporting machines like date coding machine.

4. Auxiliary equipment available such as feeding machine, date coding machine, finished product

conveyor and insulation mixing barrel.

5. Adopt brand components and PLC to ensure machine working synchronous.

6. All connect with product parts is made of stainless steel 304, to meet with GMP and CE standard.

7. All the works of bag making,measuring,filling,sealing,cutting and counting can be done automatically,

at the same time,it can also according to the demand of customers printing batch number and other

functions.

8. Auxiliary equipment:Heating, heat preservation mechanism, diaphragm pump, coding machine,

dust-collect, etc.

9. Pneumatic system for vertical and horizontal sealing.

Machine parameters

Type

XLY-480

Film width (max)

480mm

Size of bag

L:45-150mm W:50-120-mm

Capacity

80-120bags/min

Control style

PLC control system + English interface

Case of machine

Stainless steel

Air consumption

0.8m³/min 0.8Mpa

Power

3.5KW

Power supply

380V 50HZ

Weight

450kg/400kg

Dimensions(mm)

L950*W1470*H3000mm

Sealing style

Pillow/back bag

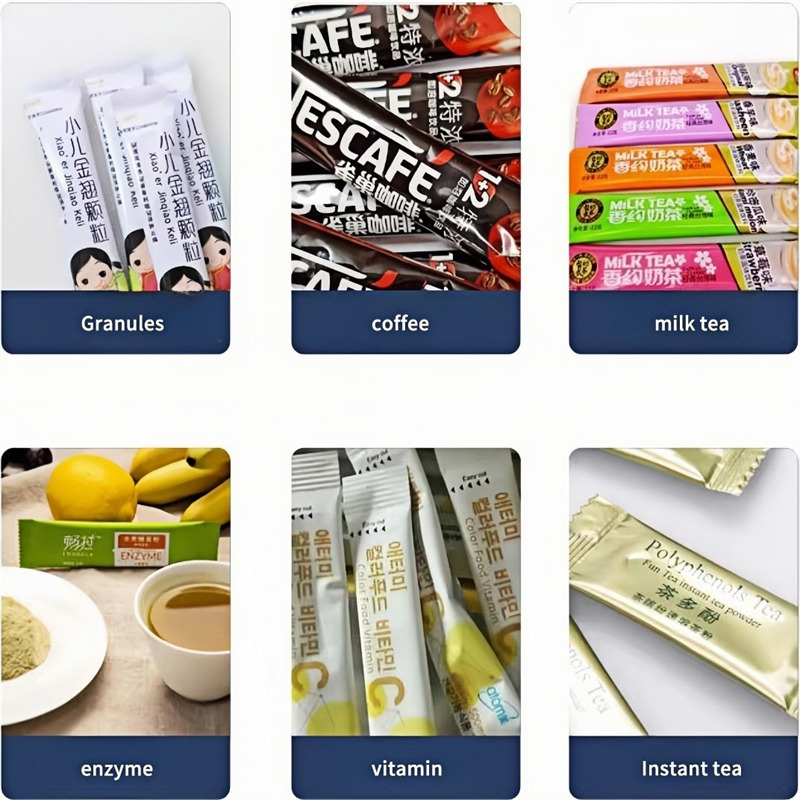

Application

It is suitable for automatic packaging of powder products with poor fluidity in food, health care and

pharmaceutical industries,such as: freeze-dried powder, protein powder, gastrodia powder, pueraria

powder, stone meal powder, notoginseng powder, whole grain powder, meal replacement powder ,

milkshake powder, ganoderma powder, bear bile powder, milk powder, coffee powder, solid beverage,

etc.