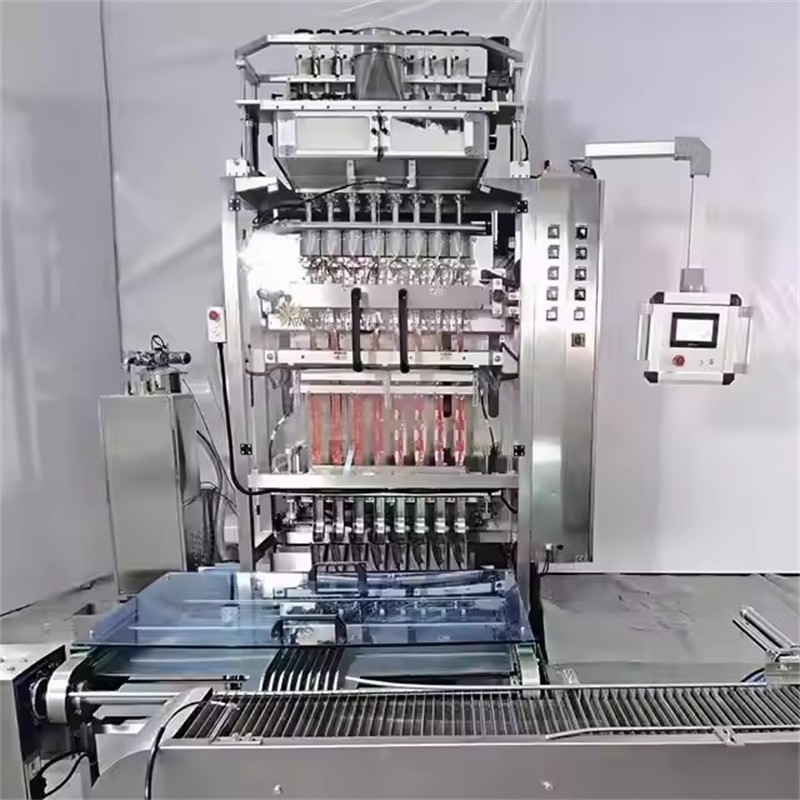

XLY-1 Powder Multi Lane Packing Machine

Product Advantages

1.Advanced performance, high strength, low noise, compact structure, stable operation, easy maintenance,

sealing, filling,printing, notch cutting, cross cutting, until the finished bag output can be completed at one

alternating multiple times once sealing. Sealing tightly.

And with high packing speed, pouch shape smoothly,delicate appearance, high packing efficiency.

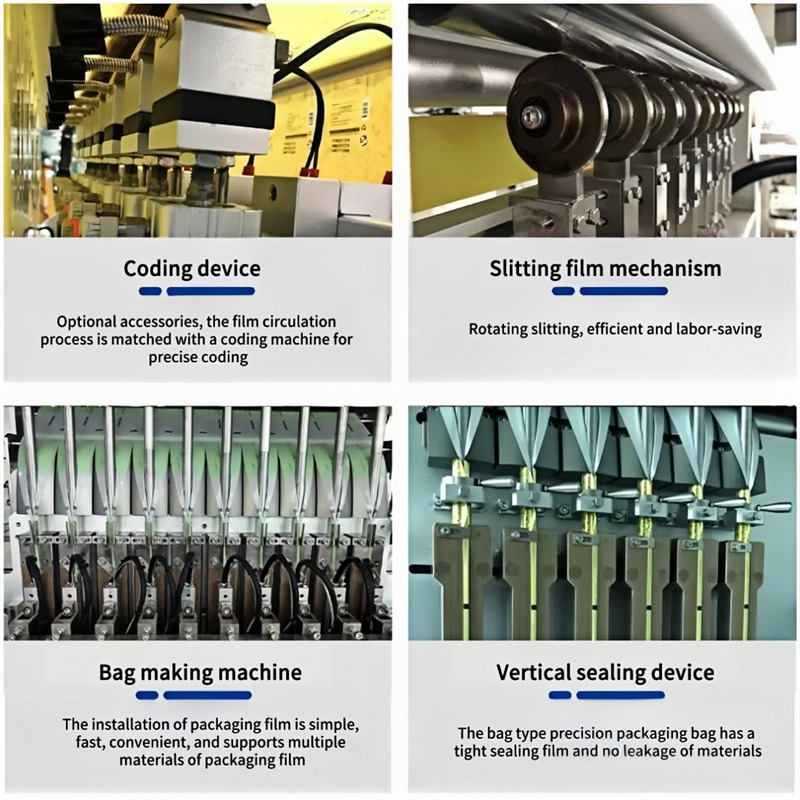

5.Quick and convenient adjustment. The bag length can be adjusted without changing the mould.

And the vertical seal,transverse sealing, filling, cutting and other implementing agencies can be

adjusted through the man-machine interface.

Machine parameters

Type

XLY-1

Lane number

4-16

Filling Method

Auger

Capacity

Max.40 cycle/min

Sachet size

L50-180mm;W20-100mm

Sealing type

Back sealing/ Stick bag

Cutting type

1.Straight cutting; 2.Zig zag cutting;Rounding cutting; Die-cut

Air & Power

0.8Mpa 0.8m³/min;7.5kw

Dimension & weight

1700*1600*2500mm;900kg

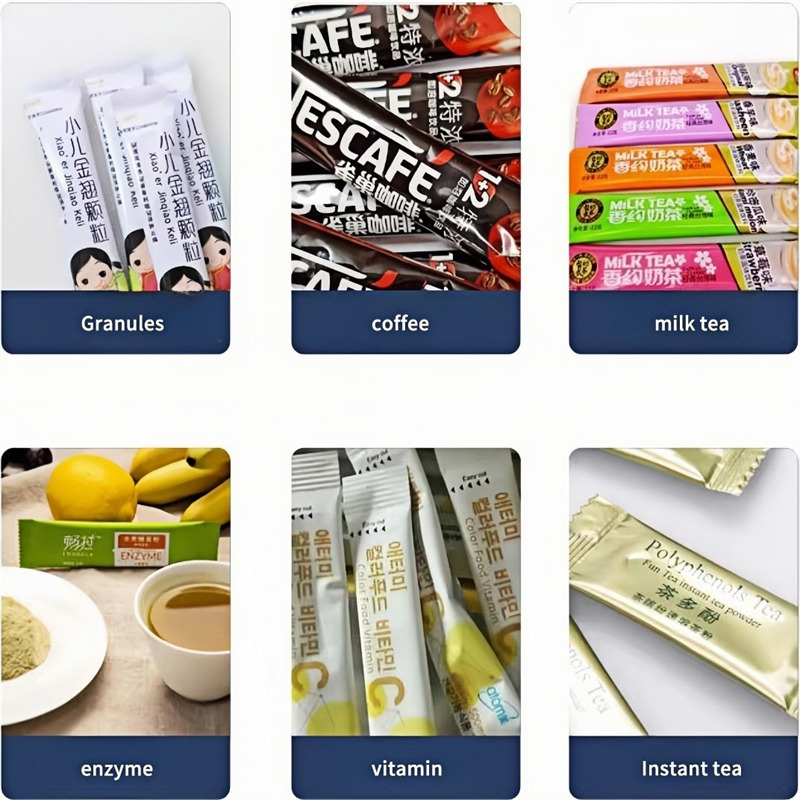

Application

It is suitable for automatic packaging of powder products with poor fluidity in food, health care and

pharmaceutical industries,such as: freeze-dried powder, protein powder, gastrodia powder, pueraria

powder, stone meal powder, notoginseng powder, whole grain powder, meal replacement powder ,

milkshake powder, ganoderma powder, bear bile powder, milk powder, coffee powder, solid beverage,

etc.