XLY-160 Liquid Premade Pouch Packing Machine

Product Details

Product advantages

1.Small size, low weight to be manually put into the lifter, without any space limitation.

2.Low power requirement:220V voltage, no need dynamic electricity.

3.operation positions, low maintenance, high steadily.

4.Fast speed, easy to be matched with other equipments, Max55bags/min .

5.Multi-function operation, run the machine by pressing only one button, no need professional training.

Good compatibility, it can suit different types of irregular shapes of bags, easy to change the bag types

without adding extra accessories.

Machine parameters

|

Model |

XLY-160 |

XLY-210 |

XLY-260 |

XLY-320 |

|

Bag width |

80*160MM |

90*210MM |

150*260MM |

200*320MM |

|

Bag length |

100*190MM |

110*330MM |

150*400MM |

150*500MM |

|

Packing speed |

20-70BAGS/MIN |

20-60BAGS/MIN |

10-60BAGS/MIN |

10-50BAGS/MIN |

|

Power |

3KW 50HZ |

3.5KW 50HZ |

3.5KW 50HZ |

3.5KW 50HZ |

|

Weight |

600KG |

900KG |

1100KG |

1500KG |

|

Packing size L*W*H |

1400*900*1050MM |

2150*1350*1300MM |

2450*1350*1350MM |

2800*1350*1350MM |

|

Main standard parts for mini liquid pouch packing machine 1. Code printer 2. PLC control system 3.Bag opening device 4. Vibration device 5.Cylinder 6. Electromagnetic valve 7. Temperature controller 8.Vacuum pump 9. Inverter 10. Output system |

||||

Application

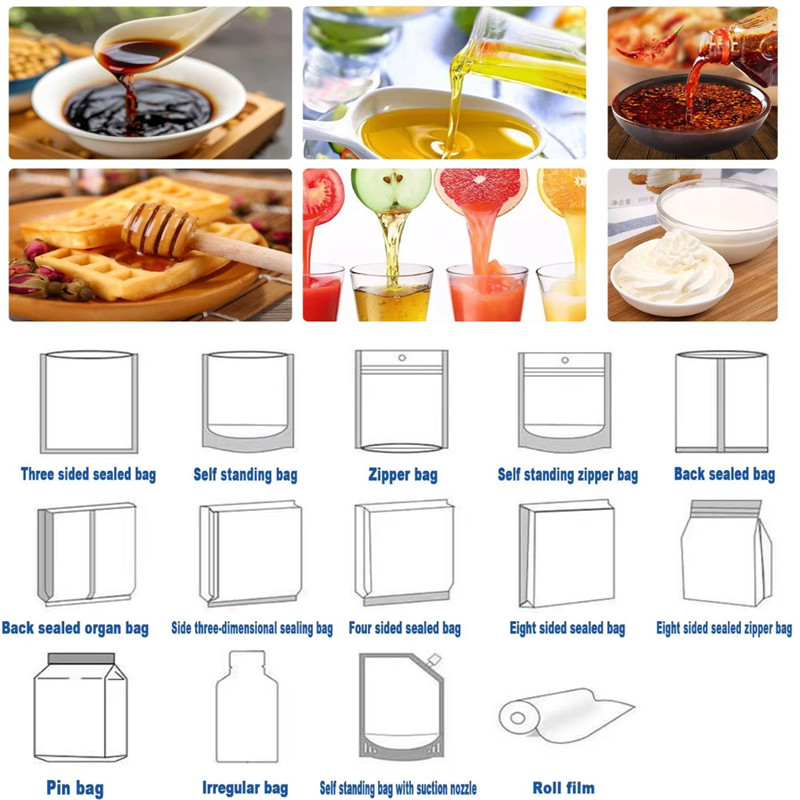

This machine is suitable for doypack bag packaging of liquids, such as cream,Skin care, soy sauce,

chili sauce,honey, ketchup, tartar, liquid butter, juice, milk, etc.

As a multi-functional packaging machine, it supports a variety of pouch types. Such as: stand up

pouch, hand pouch,zipper pouch,3 sides seal pouch, 4 sides seal pouch, spout pouch, paper pouch,

flat bottom pouch and other laminated pouch.