XLY-210Y Liquid Mini Doypack Packing Machine

Features and advantages

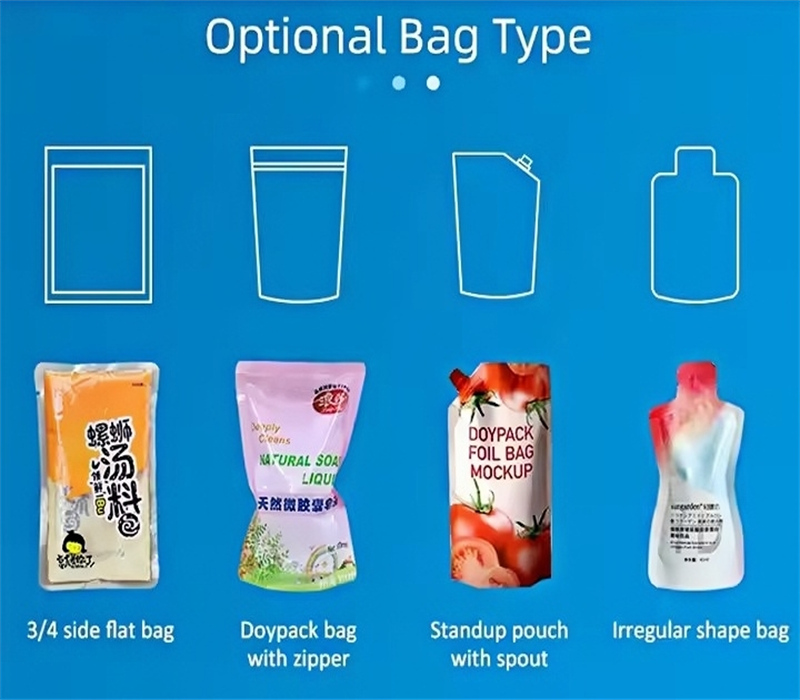

1.Different machine models available to meet a wide range premade bag size.

2.Customized main machine structure for various kinds of bag shapes.like doypack zipper bag ,4 side

seal bag,strand up bag and irregular bag,etc.

3.Multiple working station to meet fully automatic process of bag pickup,date printing,bag opening,filling,

bag arranging ,sealing and output.

4.With upgrade PLC control system,machine is easy for operation on touch screen of parameter setting.

5.Machine can equipment with different metering system like weigher,liquid pump,auger filler,bucket

chain for different kinds of product filling and packing in premade bag.

Machine parameters

| Model | XLY-160Y | XLY-210Y | XLY-260Y | XLY-320Y |

| Bag width | 80-160 mm | 90-210 mm | 150-260 mm | 200-320 mm |

| Bag length | 100-190 mm | 110-330 mm | 150-400 mm | 150-500 mm |

| Packing speed | 15-60 bag/min | 15-45 bag/min | 10-30 bag/min | 10-25 bag/min |

| Voltage | 220V | 380V | 380V | 380V |

| Power supply | 3kw 50/60Hz | 3.5kw 50/60Hz | 4kw 50/60Hz | 4.5kw 50/60Hz |

Application

This automatic doypack packing machine is customized for different kinds of liquid products like laundry

detergent, softener,gel, sauce, paste, jam, oil, juice, drinks, etc. metering, filling, sealing and packing

into premade bags. (3 or 4 side seal bag,doypack bag, spout bag, irregular shape premade pouches,

etc.)