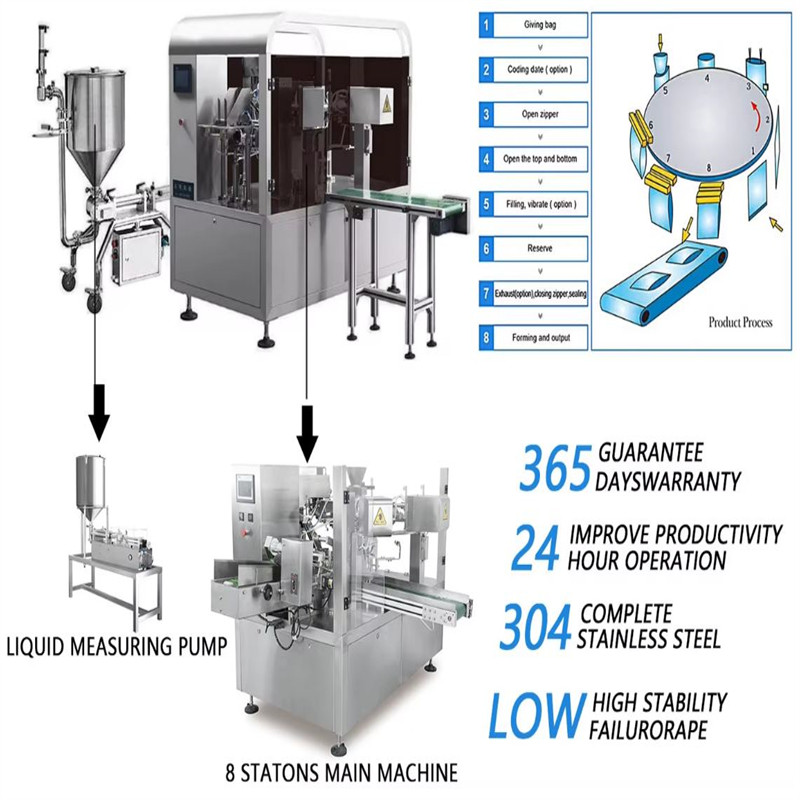

XLY-X8210 Liquid Doypack Packing Machine

Machine Features

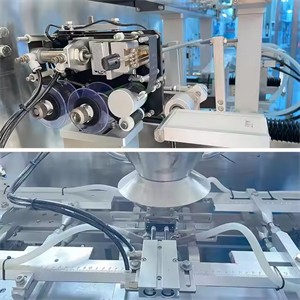

2.Single shaft ad the CAM design, packing speed faster, more stable operation.maintenance easier and

reduce defective rate;

4. Advanced design concept, reduce the loss of packaging material, ensure the stability of the operation of

equipment,prolong the operation of equipment life;

5.simple and convenient operation, using advanced PLC+POD (touch screen)electrical control system,

man-machine interface friendly;

6.The machine has a wide range of packaging, packaging liquid, paste, powder particles, solid materials

just according to different materials to choose different metering device can be;

7.This machine USE s the prefabricated packing bag, the packing pattern is perfect,the sealing quality is

good, thus enhances the product quality and the class.

Machine parameters

1.code printer

2. PLC control system

3. Bag opening device

4. Vibration device 5.Cylnder

6. Electromagnetic valve

7. Vacuum pump

1.code printer

2. PLC control system

3. Bag opening device

4. Vibration device 5.Cylnder

6. Electromagnetic valve

7. Vacuum pump

1.code printer

2. PLC control system

3. Bag opening device

4. Vibration device 5.Cylnder

6. Electromagnetic valve

7. Vacuum pump

1.code printer

2. PLC control system 3. Bag opening device

4. Vibration device 5.Cylnder

6. Electromagnetic valve

7. Vacuum pump

Type

XLY-X8210

XLY-28260

XLY-X8320

Application

Machine workstation

Eight workstations

Eight workstations

Eight workstations

Protein Powder Premade Bag Packaging Machine

Bag material

Composite film, PP, PE, etc

Composite film, PP, PE, etc

Composite film, PP, PE, etc

Premade bag packing machine

Weighing Range(g)

10-1000

10-2000

10-3000

Filling range can be customized

Packaging speed (bags/minute)

0-60

0-60

0-60

speed can be customized

Bag size(mm)

W70-210xL100-300

W90-260xL100-350

w150-320xL150-450

bag size can be customized

Bag type

Zipper bag, stand up bag, 3-side sealed bag, 4-side sealed bag, shaped bag, etc

Zipper bag, stand up bag, 3-side sealed bag, 4-side sealed bag, shaped bag, etc

Zipper bag, stand up bag, 3-side sealed bag, 4-side sealed bag, shaped bag, etc

bag size can be customized

Gas consumption(m3/min)

0.6

0.6

0.6

0.6

supply voltage

2.5KW 3P 380V 50/60HZ

2.5KW 3P 380V 50/60HZ

2.5KW 3P 380V 50/60HZ

power can be customized

Machine weight

1300

1300

1300

1300

Main standard parts

Application

Liquid doypack /paste type: detergent, rice wine, soy sauce, rice vinegar, fruit juice, beverage, tomato

sauce, peanut butter, jam, chili sauce, bean paste,etc.