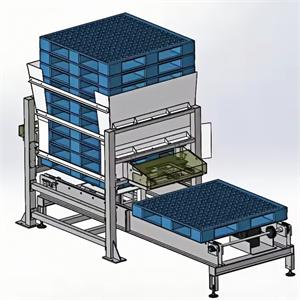

XLY-689 Auto Tablet Counting Bottling Machine

Machine parameters

Model

XLY-689

Production capacity

70 bottles/min

Voltage

380/220V 50Hz(customized)

Power

1.2KW

Weight

550kg

Outline dim.

1600×1650×1500mm

machine description

1.Feeding and Orientation: The bulk quantity of pills or capsules is initially loaded into a hopper. The

count bottling machine then orients the items to ensure they are positioned correctly for counting.

2.Singulation: The oriented pills or capsules are separated or singulated from the bulk using mechanisms

such as vibrating channels, rotating disks, or other devices. This ensures that individual items are

presented for counting.

3.Counting Mechanism: The counting machine employs a counting mechanism that typically uses sensors,

photoelectric cells, or other technologies to detect and count each passing item accurately. The counting

process is often synchronized with the singulation mechanism to ensure precision.

4.Reject Mechanism: If any irregularities or discrepancies are detected during the counting process, a

reject mechanism may be activated to remove faulty or excess items, maintaining accuracy in the count.

5.Collection and Packaging: After counting, the pills or capsules are collected in a receptacle or conveyed

to the packaging line. The counting machine is often integrated into a larger packaging system, facilitating

the seamless transfer of accurately counted items for further processing and packaging.

Application

The working principle of tablet counting machine, also known as a tablet or capsule counting machine,

involves several steps to accurately count and fill a predetermined number of pills or capsules. These

machines are commonly used in pharmaceutical, nutraceutical, and other industries where precise

counting and packaging are essential.