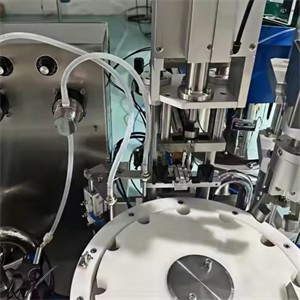

XLY-201A Automatic Test Tube Drink Filling and Capping Machine

Machine description

The filling machine is also widely used in the production industry, and the equipment exists in the wine,

beverage, perfume, medicine and other industries. Because of its stable mechanism, excellent performance,

fast speed, simple operation, automatic filling, capping, capping, and bottle-out, it is the first choice for

cap-locking equipment for manufacturers of bottled products.

Machine feature

1. It is applicable to different-shaped bottles and plastic bottles: PP, PE, PVC, glass bottle and mould

bottle. The bottle in and bottle out has specialized structure. It doesn't drop bottles or nip bottles

2. PLC control, simple and easy to operate.

3. The part which touches the liquid medicine is made of 316L stainless material completely,meeting

the requirement of GMP.

4. It can be connected with the bottle-washing machine and the label-attaching machine to form a

complete set of produce line.

Machine parameters

| Type | XLY-201A | |||||||

| Filling capacity | 2ml-30ml (larger filling capacity can be customized) | |||||||

| Number of filling heads | 1/2 /4(can be customized according to customer needs) | |||||||

| Voltage | 220V; 50/60HZ | |||||||

| Power | 2.2 kw | |||||||

| Applicable liquids | water,soft drinks,beer,dairy products,beverages with pulp, tea,coffee, hot drinks, and more liquids,please refer to the | |||||||

| Filling accuracy | ±0.5% (error depends on caliber, filling time, temperature, etc.) | |||||||

Application