XLY-350X Automatic Tableware Toothbrush Comb Packaging Machine

Feature

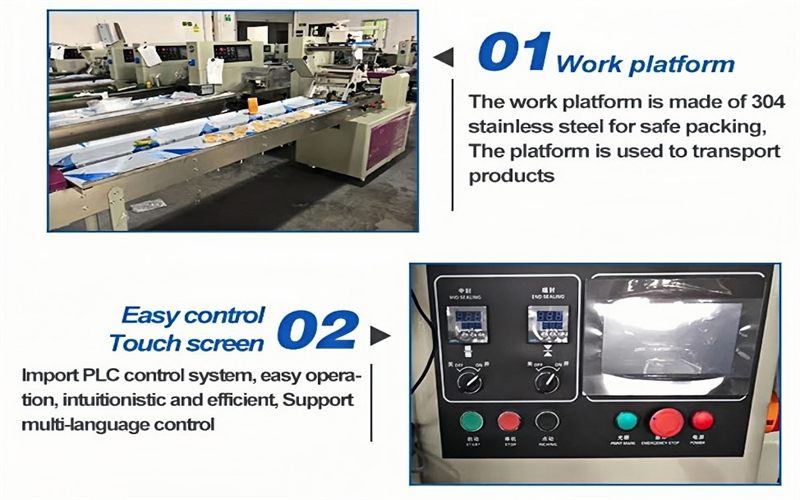

1.Servo control, automatically detect product length and cut, operator needn't to adjust the unloading

working, saving time and saving films.

2.Human-machine operation, convenient and quick parameter setting.

3.Self diagnosis failure function, clear failure display.

4.High sensitivity optical electric color mark tracking &digital input cut position which makes the sealing&

cutting more accurate.

5.Separate control to temperature, suitable for various packing materials.

6.Stopping the machine in selected position, no sticking to the knife and no waste packing film.

7.Simple driving system, reliable working, convenient maintenance.

8.All the controls are achieved by software, convenient for function adjusting and upgrading.

Machine parameters

| Model | XLY-350X |

| Production capacity | 20-130 bags/min |

| Diameter of film roll | maximum 320mm |

| Packaging film width | the widest 700mm |

| Air pressure | 0.5-0.7Mpa |

| Machine noise | less than 80db(A) decibel |

| Rated frequency | 50Hz |

| Rated voltage | AC220V |

| Transmission power | 4.2Kw |

| Total weight of the machine | 720Kg |

| Machine size | length 4380mm*width 980mm* height 1480mm |

Application

Applicable for packing various solid regular objects, such as moon cake, bread, biscuits,candies, snow

cakes, custard cakes, chocolates, instant noodles, medicines, commodities, hardwares, carton, trays

and etc.