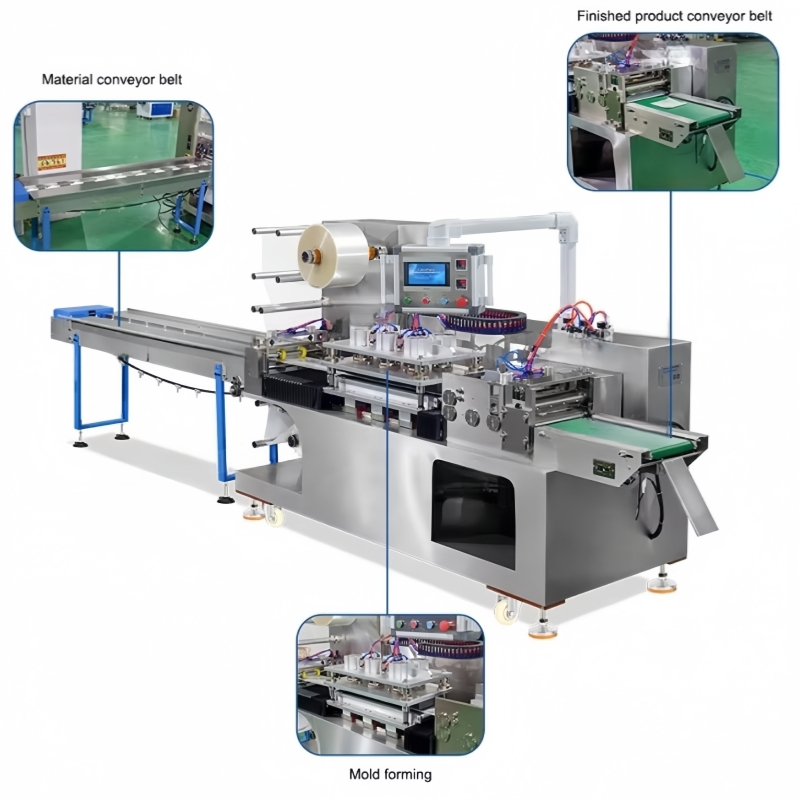

XLY-652 Continuous Four Side Seal Packaging Machine

Feature

1.High-precision Cutting: advanced cutting technology is adopted to cut the ports of the bags accurately

to ensure that the cutting lines are neat and no burrs or misalignments are produced, which guarantees

the quality of the package and the appearance effect.

2.Flexibility and Adaptability: It can adapt to the bags of different food, medicine, cosmetic and other

products, and supports bags of various materials, such as plastic film, paper bags, and so on.

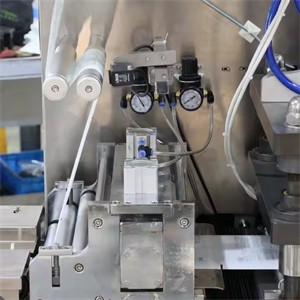

3.Automatic Adjustment: It can accurately identify the packaging materials in different positions on the

roll and automatically adjust the tension to maintain the tightness of the package, avoiding the problem

of slack or overstretching and ensuring the quality of the package.

Machine parameters

| Item/model | XLY-652 |

| Processing capacity | 30-100 bags/min |

| Applicable raw materials | single mask |

| Bag size | 500 mm long × 150 mm wide |

| Roll film size | Φ≤320 mm, width 200-600 mm, inner diameter of paper core 76.2mm |

| Roll film material | paper aluminum plastic, pure aluminum, aluminized, coated paper, composite transparent film, etc. Total power 220v 50Hz motor |

| Total power | 220v 50Hz |

| Heating | 3.2KW |

| Air consumption | ≥30m3/h (self-provided) |

| Pressure | 0.6-0.8Mpa |

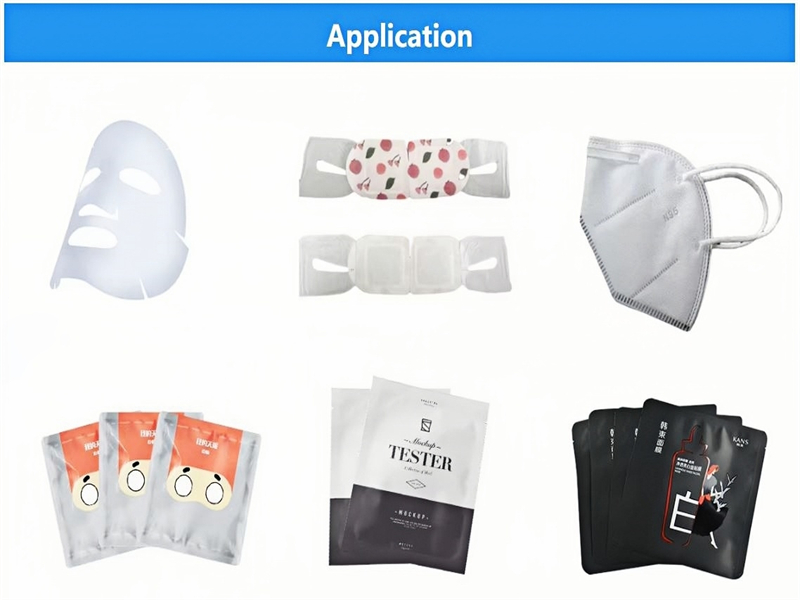

Application

This machine can be applied to sheet products that require sealing on four sides, such as the following

products:

1. Masks products: surgical mask, kn94 mask, disposable masks;

2. Daily necessities: condom, cards, wet wipes, alcohol wipes, mobile phone stickers, mobile phone

cases, hardware, small plastic parts, craft gifts, sheets, toys, stickers, non-woven fabrics, cotton pads;

3. Supplies: ointment sticking, plaster paste, analgesic paste, analgesic paste, gauze, medical paste,

antipyretic paste, belly button paste, moxibustion paste, early pregnancy test paper, cooling paste,

Gutong paste, alcohol cotton pad, motion sickness paste, artificial Breathe;