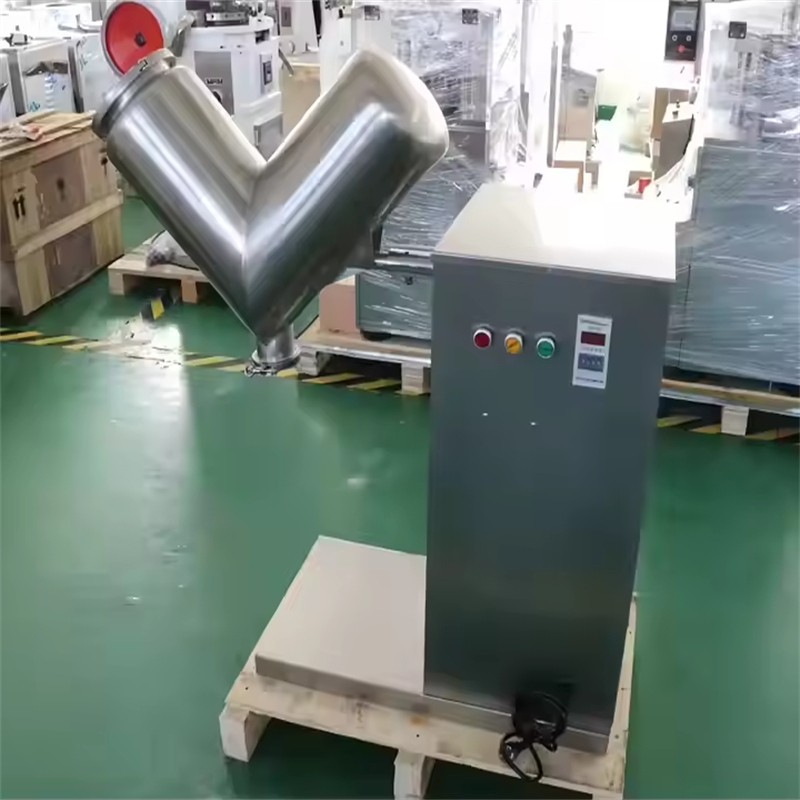

XLY-30 V Type Seasoning Chilli Spice Powder Mixing Machine

Product parameters

| Model | XLY-30 |

| Rated Voltage | 220V/50hz |

| Motor power | 750w |

| Drum volume | 30L |

| Appropriate | 15L |

| Mixing speed | 20r/min |

| Appropriate Weight | 10kg-20kg(Actual look at the material density specificgravity) |

| Dimensions | 800*600*1000mm |

| Weight | 120kg |

Feature

(1)The structure is advanced, easy to operate, and the operation is safe and reliable. The cantilever

double spiral shaft has no bottom bearing, which eliminates faults caused by powder infiltration of the

bottom bearing.

(2) The mixing speed is fast and the quality is uniform. The double helix of this machine is arranged in

an asymmetric manner,which expands the mixing range from large to small, making it more suitable for

mixing materials with significant differences in specific gravity and mixing ratios.

(3) The energy-saving effect is significant, and the energy consumption of this machine is only one tenth

of that of the drum type V-shape mixer.

(4) The wear and pressure of granular materials are minimal, and there is no overheating reaction when

mixing heat-sensitive materials.

(5) The mixed formulation is stable and does not exhibit stratification or segregation.

(6) This machine is sealed and dust-free, with simple operation, convenient maintenance, and long service

life. In addition,according to user requirements, conical pressure vessels can be made for pressurization

or vacuum operation.

(7) The self transmission and revolution of this machine are completed by a set of motors and a cycloidal

needle transmission reducer.

Application

Tailored for a multitude of industries, it is perfect for applications in medicine, food,feed, fertilizer, ore,

and beyond.

Medicine: Perfectly suited for blending materials such as capsule granules, Chinese medicine flavorings,

as well as powder and granule formulations of traditional Chinese medicine.

Feed: Expertly crafted to accommodate a wide array of feeds, including those for fish, poultry, wild

animals,and birds, ensuring a comprehensive feed mix.

Food: Ideal for the meticulous mixing of condiments, additives, vitamins, and other essential food

ingredients.

Ore: Engineered to proficiently mix an assortment of powdered or granular ores and similar materials.