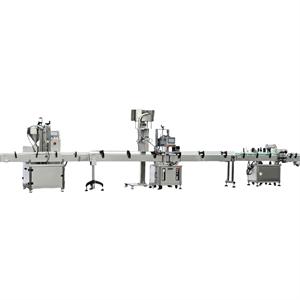

XLY-120 Automatic Crawler Capping Machine

Feature

1.Advanced HMI operation, PLC control;

2.Automatic cap stamping and cap hanging; afterwards, bottles are calibrated before being fed to

the capping mechanism by the bottle-clamping belt. Bottle caps will be pressed tighter and tighter

thanks to the capping belt design.

3.Capping speed is fast and conformance rate is high. Sealing performance is good after capping.

4.The surface is made of 304 stainless steel.

Machine parameters

| Item | XLY-120 |

| Cap diameter | Φ45-160mm |

| Bottle diameter | Φ50-110mm |

| Bottle height | 60-300mm |

| Screwing speed | ≤6000 barrels/min |

| Power | AC220V 50/60Hz 1.1KW |

| Weight | 650㎏ |

| Pressure range | 0.4-0.6Mpa |

| Host dimension | 2000×930×2100mm |

Application

It applies to capping and sealing of bottles for soy source, vinegar and vegetable oil.

INQUIRY