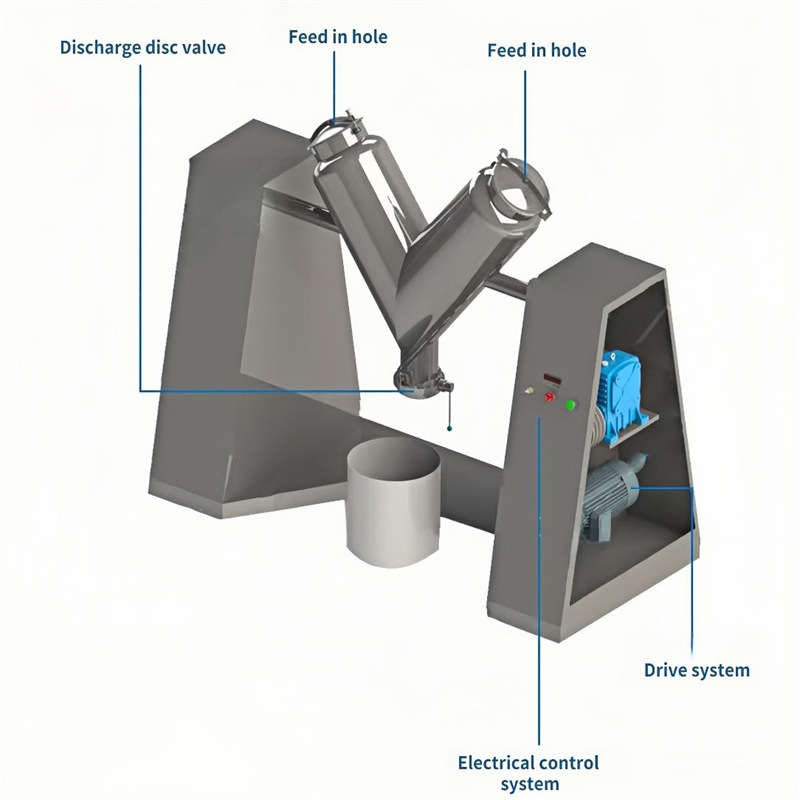

XLY-0308 High Efficient Stainless Steel V Type Mixer Machine

Product description

The rotary mixer is mainly suitable for mixing powder and granular materials in the food,pharmaceutical,

chemical, and other industries; Suitable for crushing with different specific gravity or mixing with other

additives. It is widely used in the mixing of feed, food, pesticides, dyes, pigments, plastics, resins, chemical

raw materials,seasonings, cosmetics, medical products, and various powder additives, and can be

used in the mixing of powders with trace amounts of liquid.

Working principle: The sealed mixing cylinder adopts the principle of gravity diffusion for mixing, and

continuously performs rotary motion to make the material flip up, down, inside, and out, achieving the

purpose of mixing. The mixing rate reaches over 99%, making it an ideal product among various mixers

at present.

Feature

(1)The structure is advanced, easy to operate, and the operation is safe and reliable. The cantilever

double spiral shaft has no bottom bearing, which eliminates faults caused by powder infiltration of the

bottom bearing.

(2) The mixing speed is fast and the quality is uniform. The double helix of this machine is arranged in

an asymmetric manner,which expands the mixing range from large to small, making it more suitable for

mixing materials with significant differences in specific gravity and mixing ratios.

(3) The energy-saving effect is significant, and the energy consumption of this machine is only one tenth

of that of the drum type V-shape mixer.

(4) The wear and pressure of granular materials are minimal, and there is no overheating reaction when

mixing heat-sensitive materials.

(5) The mixed formulation is stable and does not exhibit stratification or segregation.

(6) This machine is sealed and dust-free, with simple operation, convenient maintenance, and long service

life. In addition,according to user requirements, conical pressure vessels can be made for pressurization

or vacuum operation.

(7) The self transmission and revolution of this machine are completed by a set of motors and a cycloidal

needle transmission reducer.

Product parameters

| Product Model | XLY-0308 | XLY-0309 |

| Machine Material | Stainless steel 304 for all parts | |

| Voltage | 220v/380v | |

| Power | 1500w | 2500w |

| Machine Size | 320*150*270mm | 400*150*270mm |

| Capacity | 220L | |

| Weight | 30KG | 45KG |

Application