XLY-X-400 Stainless Steel Vibrating Screen Machine

Product parameters

| Model | Diameter | Layer | Power | Vibration frequency |

| XLY-X-400 | 400mm | 45660 | 0.37KW | 1500rpm |

| XLY-X-600 | 600mm | 45660 | 0.55KW | 1500rpm |

| XLY-X-800 | 800mm | 45660 | 0.75KW | 1500rpm |

| XLY-X-1000 | 1000mm | 45660 | 1.5KW | 1500rpm |

| XLY-X-1200 | 1200mm | 45660 | 1.5KW | 1500rpm |

| XLY-X-1500 | 1500mm | 45660 | 2.2KW | 1500rpm |

Feature

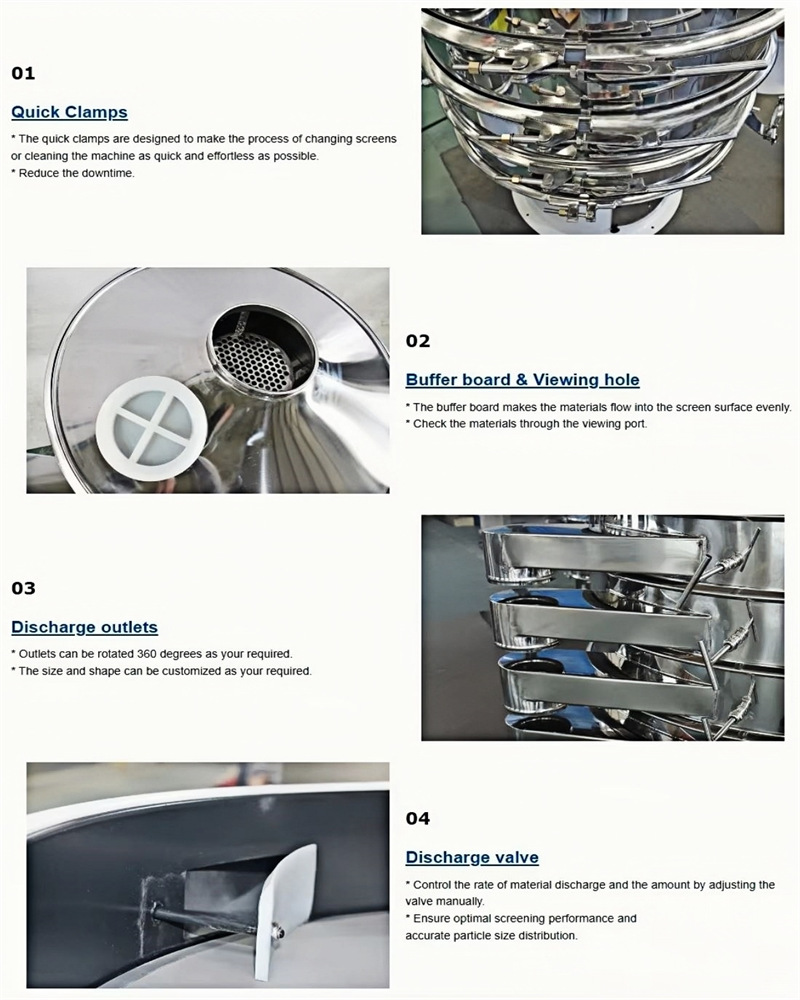

1. It is convenient and quick to change the screen mesh. It only takes 3 to 5 minutes. The box adopts

a fully enclosed structure and a fast ring design. It is a high-precision subdivision and screening machine.

2. The motor power adopts the middle flange motor, which has large power, which makes the horizontal,

vertical, and inclined three-dimensional power more prominent, and the noise is low while the power is

large.

3. A wide range of screening materials, no matter the material is dry or wet, fine or coarse, heavy or light,

as long as the material is in the range of 10-400 mesh, it can be screened, even if the material is liquid or

slurry, as long as the material is 600 mesh It can be easily sieved within.

4. Equipped with a professional screen cleaning device, the screen will not be blocked in the process of

screening materials,which greatly improves the screening output and screening efficiency of the screen.

5. In response to the special needs of different industries, the three-dimensional vibrating screen has a

unique design, such as the edge-added type, gate type, powerful type, sealed type and other different

types.

Application