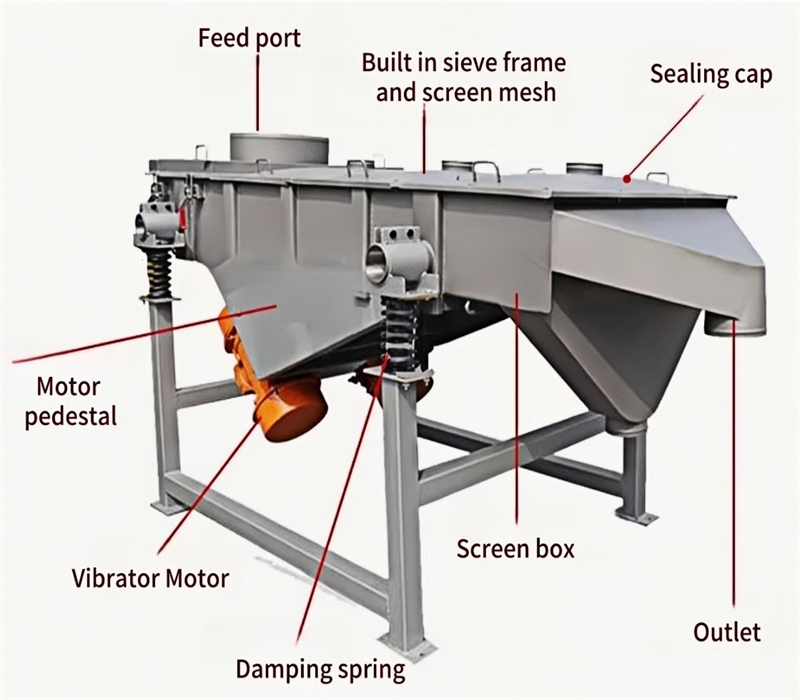

XLY-Z-520 High Quality Linear Rectangular Screening Machine

Feature

1. It can screen granular materials below 400 mesh, and the screening efficiency can reach more than

96%.

2.The 1-6 layer screen design can screen out 2-7 kinds of materials with different particle sizes at the

same time to meet the needs of different customers.

3. Double-motor drive, large excitation force, output of 20 tons/hour, energy consumption can be reduced

by 30%.

4. The linear vibrating screen adopts a fully enclosed structure, and there is no dust spillage.

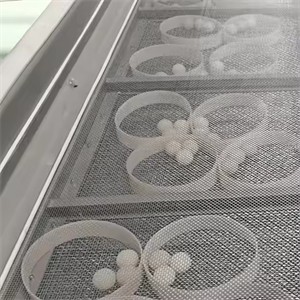

5. Screen replacement is simple and fast, only 3 to 5 minutes, and there are many choices of screen

material (nylon, PP mesh).

Product parameters

| Model | Effective screening area | Granularity size | Deck | Power(kw) | Speed(r/min) | Amplitude(mm) |

| XLY-Z-520 | 500*2000 | 0.074-60 | 45661 | 2*0.75 | 960 | 45755 |

| XLY-Z-840 | 800*4000 | 0.074-60 | 45661 | 2*1.5 | 960 | 45755 |

| XLY-Z-1030 | 1000*3000 | 0.074-60 | 45661 | 2*1.9 | 960 | 45755 |

| XLY-Z-1255 | 1200*5500 | 0.074-60 | 45661 | 2*2.2 | 960 | 45755 |

| XLY-Z-1650 | 1600*5000 | 0.074-60 | 45661 | 2*3.0 | 960 | 45755 |

Application

(1) Foods: Granulated sugar, MSG, salt, gourmet powder, grains, protein powder, soy milk,juice, freeze

-dried food, coconut granules, etc.

(2) Chemicals: resin, dye, cosmetics, plastics, rubber, ceramics, fire extinguishing agent, fireproofing

materials, etc.

(3) Medicines: Granule pills, pellets, Chinese medicine, etc.

(4) Metallurgy: Iron powder, aluminum powder, copper powder, alloy powder, refractory materials, steel

shot, aluminium oxide,electromagnetic powder, iron ore tailings, lead and zinc tailings, quartz sand,

potassium feldspar dehydration, industrial sewage,coal sludge dehydration, soil restoration, etc.

(5) Others: Carbon, activated carbon, carbon black, glass, wood flour pearl, paper, fertilizer, sulfuric acid,

etc.

(6) Liquid Sifter: Paint, coating, ciscous liquid, etc.