XLY-440 Liquid Visual Inspecting Machine

Main Features:

- High definition industrial camera &lens- High brightness strobe light source

- Deep learning AI algorithm platform - High efficiency GPU processing platform - High resolution

industry touch screen

to detect and eliminate nonconforming products in production line based on optical imaging, vision

algorithm and data integration technology. The product scratches, pits, dirt, printing and other minor

defects can be successfully identified. The products have been successfully used in the field of

medical products such as heart stents and balloons with high demand. The software has deep

learning capabilities and can constantly update itself as it is used.

Machine parameters

| Model Number | XLY-440 |

| Touch Screen | 10.1 inch color TFT touch display |

| Weighing range | 10~5000g |

| Minimum scale | 0.1g |

| Sorting accuracy | ± 0.7g~±1.5g |

| Weighing section size | L 400mm * W 300mm |

| Belt height from ground | 680mm~750mm(Customized Height) |

| Material. Surface | 304 stainless steel surface polishing |

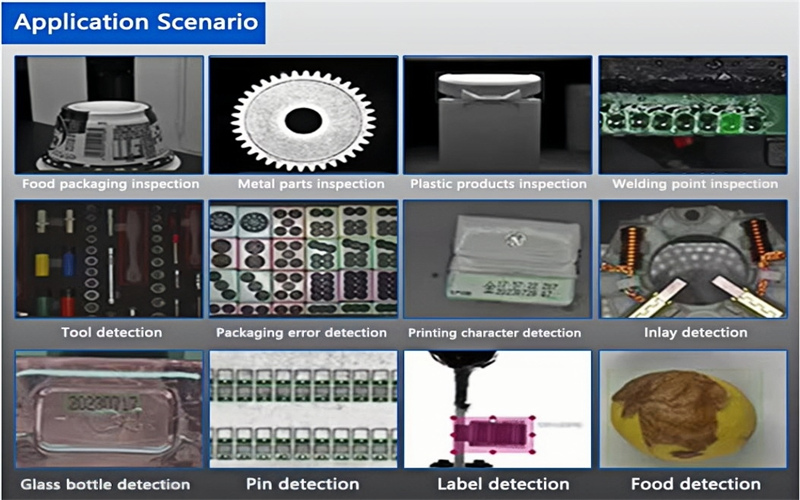

Application

The visual inspection machine can inspect the cap defects such as black spots, color differences,

impurities, threads, compression rings, broken rings, notches, burrs,flash, deformations, size, double

gaskets, reverse gaskets, inner plugs, mold numbers on bottle caps , etc and remove the defects from

the qualified ones online.

It can do Label Inspection,360 Degree Round Label inspection,Packaging Box Inspection,Packaging

Carton Inspection,Preform&Bottle Finish Inspection,Preform&Bottle Base Inspection,Can Code

Inspection,Empty Can Inspection, Fill Level and Code Inspection,Fill Level、 Cap、 Code Inspection.