XLY-L-150 High Speed Unscrambler Plastic Bottle Aluminum Can

Product parameters

Model

XLY-L-150

XLY-L-250

XLY-L-350

XLY-L-400

Production capacity (b/h)

9000

15000

21000

24000

Air source pressure (Mpa)

0.7

0.7

0.7

0.8

Air consumption(m3/min)

0.5

0.5

0.5

0.5

Suitable bottle (ml)

250-1500

250-1500

250-1500

250-1500

Main motor power (kw)

7.5

7.5

7.5

8

Weight (kg)

1800

2200

2500

2800

Feature

1. The structure is compact, simple, occupies a small area, and is easy to debug and adjust. Similar

products from other manufacturers on the market are larger in size, with a total length of more than

3 meters, which is relatively bulky.

2. When changing the specifications, no need to change any molds, and the bottles of 50-1000ml can

be used universally. The adjustment is convenient and fast. When changing specifications, you only

need to replace the number of belts in the turntable and adjust the spacing of the bottle unscrambler.

Adjust the spacing of the bottles as needed.

3. The electrical components of the whole machine are imported to ensure the service life, stability and

reliability of the equipment.

4. All plexiglass covers are equipped with inductive switches. The plexiglass cover must be completely

closed to start the machine. When the machine is running, if any plexiglass door is opened, the machine

will stop running, which is safe and reliable.

5. The connecting belt in the machine adopts one-time molding technology, which is durable and not easy

to be damaged.

6. Automatic bottle loading function, just pour the bottle into the bottle loading machine, and the turntable

is equipped with detection photoelectricity to realize automatic bottle loading when the bottle is insufficient.

Stop bottling when the bottle is full without manual intervention.

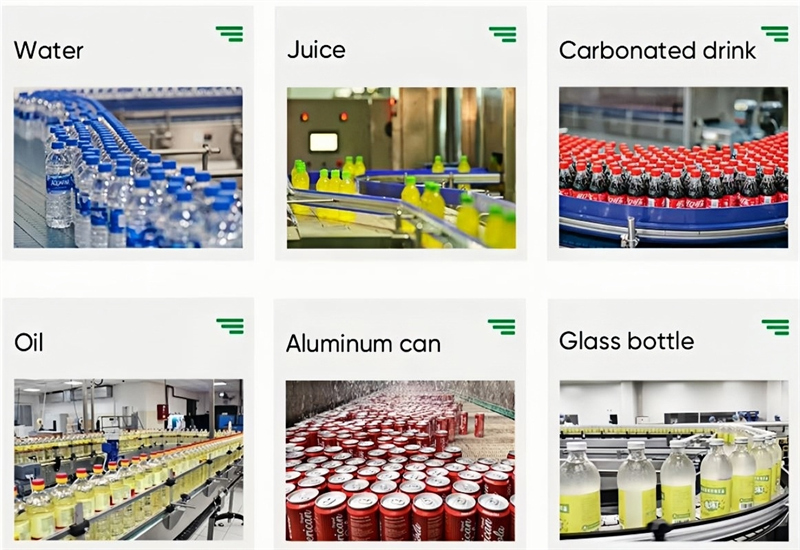

Application

It is commonly used in food, beverage, pharmaceutical, cosmetics and other industries.