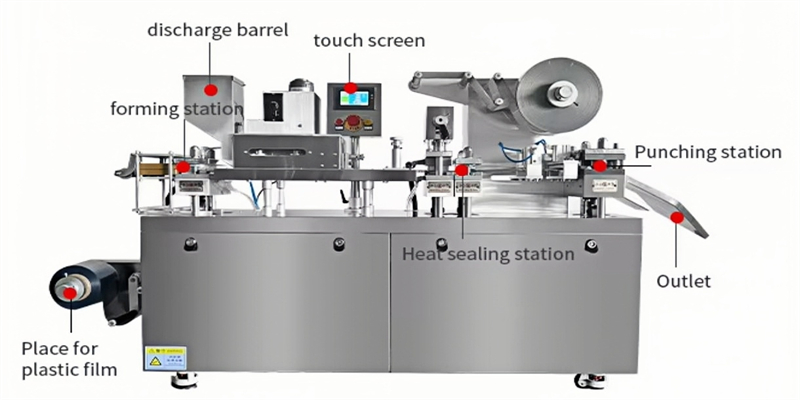

XLY-120L Full Automatic Alu PVC Blister Packing Machine

Feature

1) Adopt fast assembly molds, it is convenient and rapid to change molds.

2) Each station could be moved freely when rotates hand wheels, be adjusted and orientated accurately

based on gauge.

3) Independent working table is balcony type, it is more stable and clean.

4) Working table is sealed fully, it is more clean and safe.

5) Adopt photoelectric control system and ensure all the stations synchronization and stability.

6) Complete forming, feeding, heating-sealing, embossing, net printing, tearing line, cutting, trimming

collection automatically and accurately.

7)It is small volume and light weight, and one worker could move it easily.

Machine parameters

| Model | XLY-120L | XLY-170L | XLY-270L | XLY-360L |

| Output Capacity(pcs/h) | 2000-4000 | 3000-6000 | 2000-10000 | 4000-8000 |

| Driving Length(mm) | 30-90 | 30-120 | 30-130 | 30-150 |

| Max. Blister Size(mm) | 120×90×20 | 170×110×25 | 260×120×30 | 360×150×30 |

| Air Consumption(m³/min) | ≥0.4 | ≥0.4 | ≥0.4 | ≥0.4 |

| Max. Plastic Forming Film Size(mm) | Width×Thickness 120×(0.1-0.5) | Width×Thickness 180×(0.1-0.5) | Width×Thickness 270×(0.1-0.5) | 370×(0.1-0.5) |

| Max. Sealing Foil Size(mm) | Width×Thickness 120×(0.02-0.04) | Width×Thickness 180×(0.02-0.04) | Width×Thickness 270×(0.02-0.04) | 370×(0.02-0.04) |

| Voltage | 220V | 220/380V | 220/380V | Customized |

| Power(kw) | 4.5 | 6.5 | 8.5 | 13 |

| Weight (kg) | 530 | 1100 | 2000 | 2800 |

| Dimension(mm) | 1900×660×1730 | 2500×580×1530 | 3700×700×1730 | 4100×740×1750 |

Application

It is widely used for packing capsule, tablet, softgel, ampoule, vial, injection, liquid, cream, battery etc.

in pharmaceutical, medical, food and daily goods etc. industries. Also suitable for small batch production,

laboratory, hospital, college etc.