XLY-160 Powder Doypack Packing Machine

Machine Description

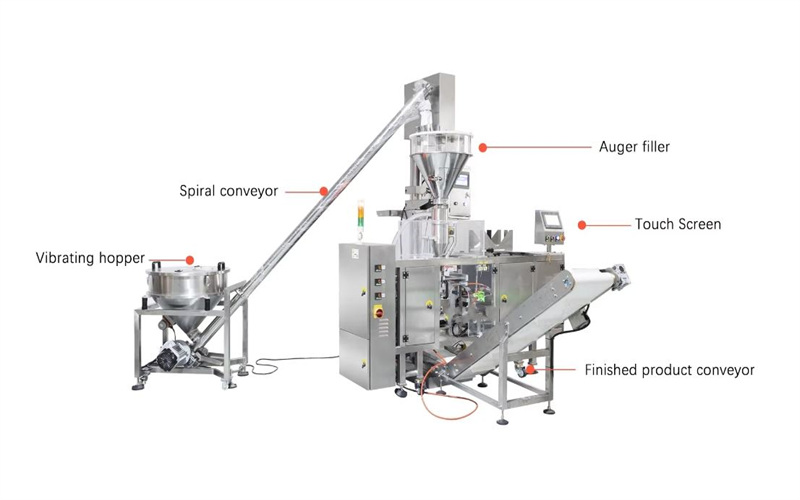

The hot doypack powder bagging system for premade bags. Engineered for a client packaging dry

powder, this system is also the perfect solution for packaging other granule or liquid products where

a premade bag is required.

Built specifically for the client’s bag sizes. This automated system conveys powder from a Hopper

up to the Powder Auger Powder Weigher via a screw conveyor.

Once weighed, it passes into the Horizontal Premade Bag Packing Machine where it is dispensed

into premade bags before the top is sealed. Bags are then conveyed to the Weight Check Weigher

to ensure each bag meets the preset weight tolerance before it is accumulated on a Rotary Table.

Unique system features include an integrated bag shaker to fully settle the product in the bag prior

to sealing, and a product rejection system to prevent the accumulation of bags that are outside of

the desired weight tolerance.

This integrated powder packaging system to weigh fill up to 3000 bags per hour to meet the needs

of the most progressive retailers.

Machine parameters

Model

XLY-160

XLY-210

XLY-260

XLY-320

Bag width

80*160MM

90*210MM

150*260MM

200*320MM

Bag length

100*190MM

110*330MM

150*400MM

150*500MM

Packing speed

20-70BAGS/MIN

20-60BAGS/MIN

10-60BAGS/MIN

10-50BAGS/MIN

Power

3KW 50HZ

3.5KW 50HZ

3.5KW 50HZ

3.5KW 50HZ

Weight

600KG

900KG

1100KG

1500KG

Packing size L*W*H

1400*900*1050MM

2150*1350*1300MM

2450*1350*1350MM

2800*1350*1350MM

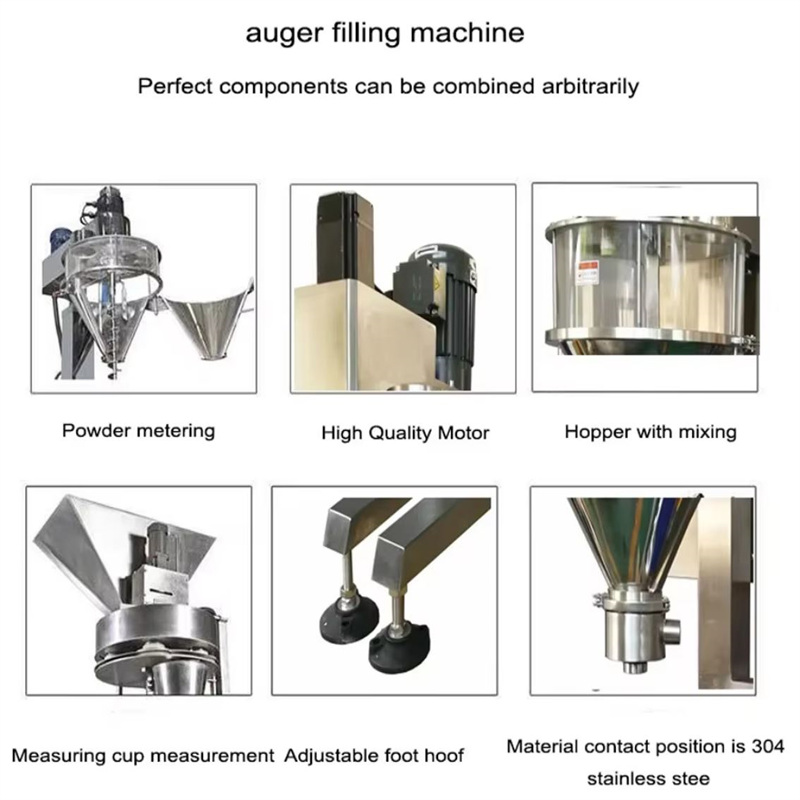

Main standard parts for mini liquid pouch packing machine

1. Code printer

2. PLC control system

3.Bag opening device

4. Vibration device

5.Cylinder

6. Electromagnetic valve

7. Temperature controller

8.Vacuum pump

9. Inverter

10. Output system

1. Code printer

2. PLC control system

3.Bag opening device

4. Vibration device

5.Cylinder

6. Electromagnetic valve

7. Temperature controller

8.Vacuum pump

9. Inverter

10. Output system

Application

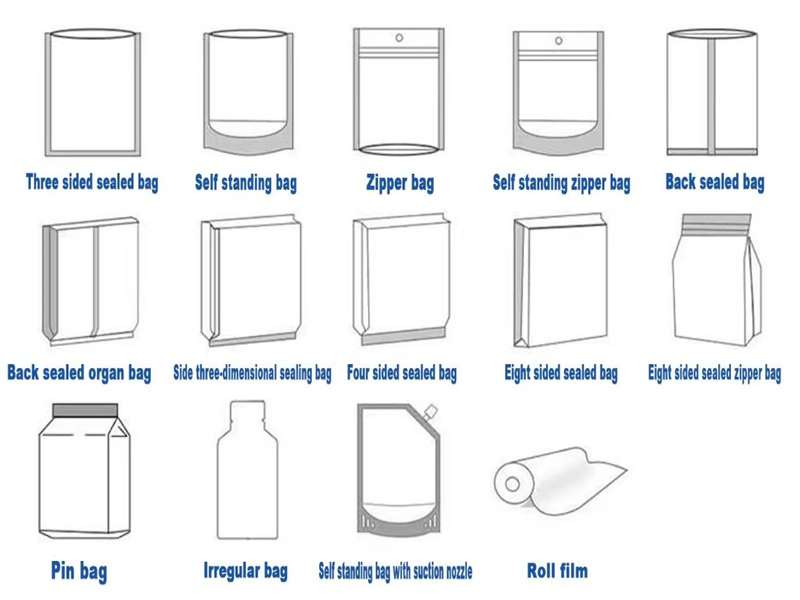

This machine is used for packing many different products: Such as milk powder, flour. starch, washing

powder, curry powder, spices, instant coffee, tea cornmeal, drink powder, bean powder, jelly powder,

maize powder, cement, peeper, paprika, fertilizer powder, herb powder, chemical powder and so on.

Support a variety of bag types, such as back sealed bag, gusseted stand up bag, quad seal bag, etc.

This machine is very popular in food, construction, fertilizer, medical and pharmaceutical.

Product Configuration