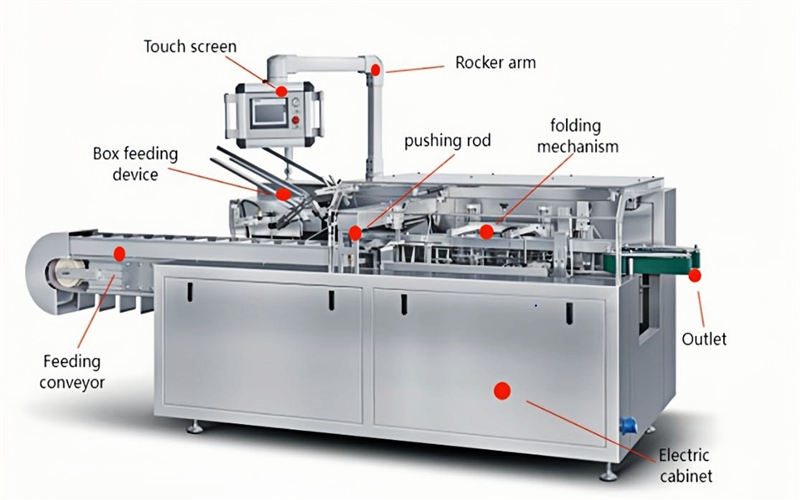

XLY-643 High Speed Fully Automatic Carton Box Packing Machine

Description

This machine is a high-tech product that integrates light, electricity, gas, and machinery, greatly improving

performance and work efficiency, meeting the requirements of fast packaging, and maintaining a stable

and reliable state during rapid operation. This machine is suitable for automatic feeding and packaging of

food, medicine, daily necessities, entertainment, hardware and other goods. The automatic feeding

mechanism is easy to adjust, and the number of boxes to be packaged can be set arbitrarily on the operation

screen. The entire process of online material testing,indentation batch number, paper tongue packaging

at both ends of the paper box (also applicable to hot melt adhesive), material shortage elimination, and

finished product output is automatically completed.

Machine Feature

1. It adopts automatic feeding, unpacking, feeding, sealing andoutput. And other packaging forms, the

structure is compact and reasonable, and the operation and adjustment are simple;

2. Servo / stepping motor, touch screen and PLC programmable control system are adopted to make

the display operation of the man-machine interface clearer and more convenient, with high degree of

automation and more humane;

3. The photoelectric eye automatic detection and tracking system is adopted, and there is no product

without suction box,which saves the packaging materials to the maximum;

4. Large range of packaging, easy adjustment, fast conversion between various specifications and sizes;

5. It is not necessary to change the mold to change the specifications, only adjustment is needed;

6. When there is no product or the product is not in place, the machine will idle without pushing the product.

When the product is restored to supply, it will automatically run. When the product is in the box, it will

automatically stop and the main drive motor overload protection device.

7. Automatic display of packing speed and counting:

8. According to customer requirements, a flip-up safety cover is adopted for easy operation and beautiful

appearance.

9.can be linked with aluminum-plastic packaging machine, pillow packaging machine, three-dimensional

packaging machine,bottling line, filling machine, labeling machine, inkjet printer, online weighing instrument,

other production lines and other equipment to achieve linked production;

10. Can design various automatic feeders and cartoning systems according to the requirements of packaging

materials;

Machine parameters

| Model | XLY-643 |

| Max size of box (mm)(L*W*H) | 200x90x70 |

| Production capacity (box/hour) | 3000 |

| Min size of box (mm)(L*W*H) | 50x25x14 |

| Specification of box | 250-350g/m2 |

| Max size of leaflet (L*W) | 210x65mm |

| Min size of leaflet (L*W) | 20x80mm |

| Specification of leaflet | 55-65g/m2 |

| Volume of air consumption | 15m3/h(pressure 0.5-0.7Mpa) |

| Machine Size | 3300x1150x1500 mm |

| Machine Weight | 1500 Kg |

Application